Why Workersbee's EV Charging Connectors Use Temperature Sensors for Safer Charging

Why Workersbee's EV Charging Connectors Use Temperature Sensors for Safer Charging

May 06, 2025

As electric vehicles (EVs) continue to grow in popularity, charging safety has become a critical concern for drivers, manufacturers, and infrastructure providers. At Workersbee, safety is not just a feature — it's a design priority. That's why every Workersbee connector, including CCS2, CCS1, GBT AC and DC, and NACS AC and DC models, is equipped with a temperature sensor.

We’ll walk you through how these temperature sensors work, why they matter, and how Workersbee uses them to create a safer and more reliable charging experience.

Which Workersbee Connectors Are Equipped with Temperature Sensors?

Workersbee integrates temperature sensors into all major EV connector types we produce, including:

CCS2 connectors (widely used in Europe)

CCS1 connectors (standard in North America)

GBT AC connectors (for Chinese alternating current charging)

GBT DC connectors (for Chinese fast DC charging)

NACS AC connectors (supporting Tesla's North American Charging Standard)

NACS DC connectors (for high-power DC fast charging under NACS)

No matter the standard or the application, the same principle applies — temperature management plays a key role in ensuring safe, stable charging sessions.

What Is a Temperature Sensor in EV Connectors?

A temperature sensor is a small but vital component embedded into the connector. Its role is simple: it continuously monitors the temperature at critical points of the connection.

Technically, temperature sensors used in EV connectors are thermistors — special types of resistors whose resistance changes with temperature. Based on how the resistance responds to temperature shifts, there are two main types:

Positive Temperature Coefficient (PTC) Sensors:

The resistance increases as the temperature rises. Example: PT1000 sensor (1,000 ohms at 0°C).

Negative Temperature Coefficient (NTC) Sensors:

The resistance decreases as the temperature rises. Example: NTC10K sensor (10,000 ohms at 25°C).

By monitoring the resistance in real time, the system can accurately estimate the temperature at the connector head, exactly where the current flows and heat builds up most.

How Does the Temperature Sensor Work?

The principle behind temperature sensors in EV connectors is both clever and straightforward.

Imagine a simple road:

If the road gets crowded (high resistance), traffic slows (temperature detected as rising).

If the road clears up (low resistance), traffic flows freely (temperature detected as cooling).

The charger continuously checks this "traffic" by reading the sensor's resistance. Based on these readings:

When everything is within a safe temperature range, charging proceeds normally.

If the temperature begins to rise toward a critical threshold, the system automatically reduces the output current to limit further heating.

If the temperature crosses a maximum safety limit, the charging session is stopped immediately to prevent damage to the vehicle, the charger, or any connected equipment.

This automatic reaction happens within seconds, ensuring a fast, protective response without needing human intervention.

Why Monitoring Temperature Matters During EV Charging

Modern EV charging involves transferring a lot of electricity, especially with fast chargers that can deliver 150 kW, 250 kW, or even higher. Where there's high current, there's naturally heat.

If heat isn't controlled, it can lead to:

Connector deformation: High temperatures can weaken materials inside the plug, leading to poor electrical contact.

Risk of fire: Electrical fires, although rare, often start with overheated connectors.

Vehicle battery damage: Thermal runaway events in batteries are often triggered by external heat sources.

Downtime and repair costs: Damaged connectors can take chargers offline, impacting network reliability.

By proactively monitoring and reacting to temperature changes, Workersbee’s connectors help prevent these risks before they escalate.

How Workersbee Uses Temperature Sensors for Safer Charging

At Workersbee, temperature sensing isn't just an added feature — it's integrated into the design from the ground up.

Here’s how we build safety into every connector:

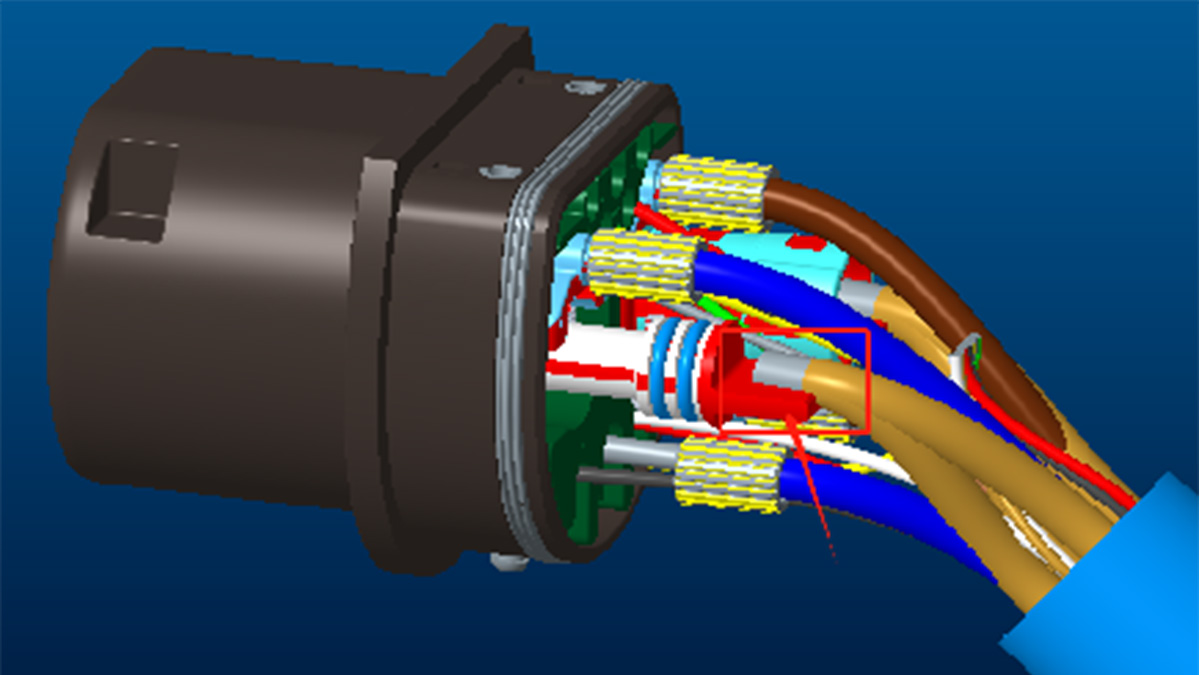

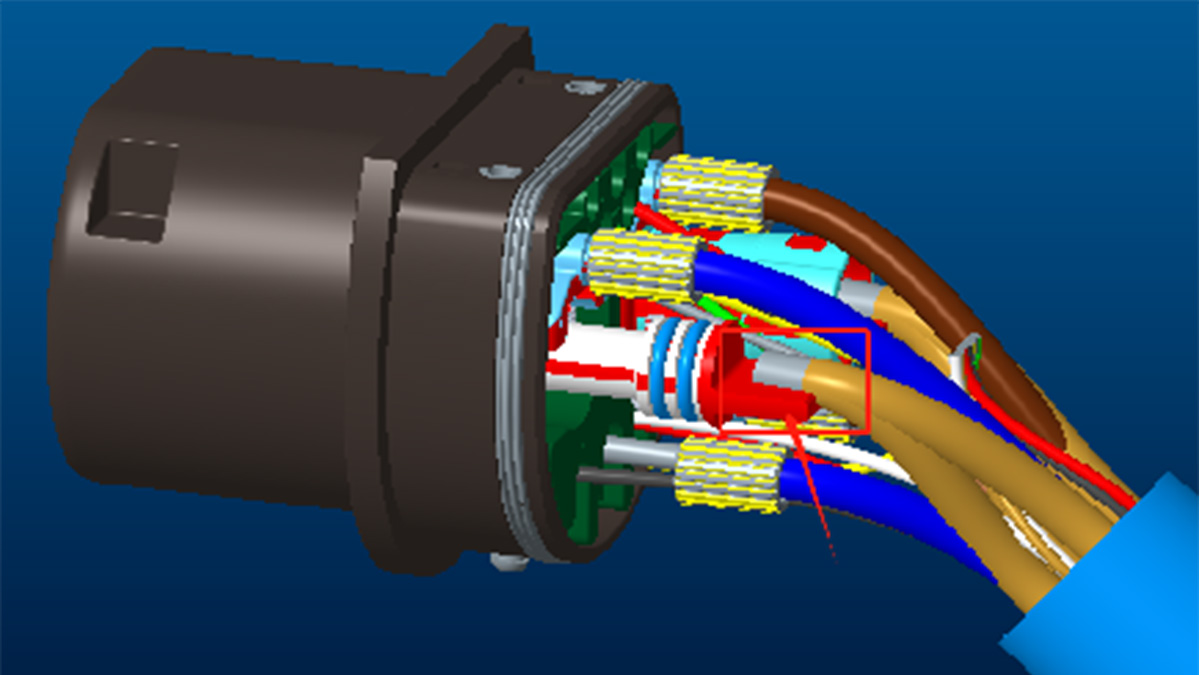

Strategic Sensor Placement

Sensors are installed close to the most heat-sensitive parts of the connector — typically the power contacts and critical wiring junctions — for the most accurate readings.

Dual-Level Protection

First Level: If temperature exceeds a warning threshold, the system dynamically reduces the current.

Second Level: If the temperature reaches the critical cut-off point, charging is stopped immediately.

Fast Response Algorithms

Our connectors work with intelligent controllers that process sensor data in real-time. This allows the charger or vehicle to react within milliseconds, preventing unsafe conditions.

Compliance with Global Standards

Workersbee connectors are designed to comply with major safety and performance standards, such as IEC 62196, SAE J1772, and Chinese national standards. These regulations often require connectors to have functional temperature protection as part of certification.

Testing for Extreme Conditions

Every connector undergoes rigorous thermal cycling and stress testing, ensuring stable performance from freezing winters to hot desert environments.

By combining smart sensor technology with intelligent system design, Workersbee delivers a safer, more resilient charging experience — whether it’s a home charger, a city station, or a highway fast-charging hub.

Real-World Example: Fast Charging in Summer

Think about a busy highway charging station in midsummer.

Multiple cars are queuing, chargers are working at full power, and ambient temperatures are already high. Without temperature monitoring, a connector could easily overheat under heavy use.

With Workersbee’s temperature sensors:

The connector continuously checks its temperature.

If it senses climbing heat levels, it automatically manages the power flow.

If needed, it gracefully reduces charging speed or pauses the session to prevent any harm — no guesswork, no surprises.

For drivers, this means greater peace of mind. For operators, it means fewer maintenance issues and better station uptime.

In the evolving world of electric mobility, charging safety has become more than just a technical requirement — it’s a basic expectation from every EV owner and charging operator.

Workersbee’s approach to connector design shows that safety doesn’t have to come at the cost of performance. By embedding temperature sensors directly into every CCS2, CCS1, GBT, and NACS connector, we ensure that each charging session is closely monitored, responsive to real-world conditions, and protected against unexpected risks.

As charging speeds continue to climb and vehicles demand faster turnaround times, the role of smart thermal management will only become more critical. At Workersbee, we are committed to refining this technology even further because safer charging is not just a goal, it’s the foundation for building a better, more reliable electric future.

Read More

Europe's EV Charging Market in 2025: Trends, Insights, and Opportunities

Europe's EV Charging Market in 2025: Trends, Insights, and Opportunities

Why Workersbee's EV Charging Connectors Use Temperature Sensors for Safer Charging

Why Workersbee's EV Charging Connectors Use Temperature Sensors for Safer Charging