A van pulls in at dusk. It is 34°C at the site. The operator says the handle feels hot and the cable drags on the curb. The next shift sees the same thing. This guide shows how to read the labels on the datasheet, then test the handle–cable pair so it lasts in your real duty cycle.

What each standard actually covers

IEC 62196-3

Defines the DC vehicle connector and inlet. It sets the geometry, keying, mating envelope, and safety checks so parts from different brands fit and work together.

IEC 62893-4-2

Defines DC charging cables that are used with a thermal management system. Think liquid cooling or an equivalent heat path in the assembly. It covers conductor class, insulation, sheath, flexibility, and endurance for fast charging.

A sibling you will meet as well: IEC 62893-4-1

This is for DC cables without a thermal management system. Same family, different use case.

What certificates prove — and what they do not

|

Buyer question |

Certificates prove |

You still need to verify |

|

Will it mate with my inlet every time? |

62196-3 defines dimensions, latch, and safe mating across brands. |

Try your target vehicles. Check latch feel with the cable at full reach. |

|

Is the cable safe for DC service? |

62893-4-2 covers DC cable design when used with thermal management; 4-1 covers DC cable without it. |

Match conductor cross-section to your current profile and cable length. |

|

Can I run 300–350 A on hot afternoons? |

Test points exist under defined lab conditions. |

Run a site trial at your airflow, pedestal geometry, and ambient temps. |

|

Will it survive winter and summer? |

Standardized cold bend, heat aging, torsion, and flame tests are applied. |

Add local stress: UV, salt spray, road grit, and the cleaners your crew uses. |

|

Is service straightforward? |

Not directly in scope. |

Ask for swap guides, torque values, and spare kits. Time a trigger or seal change. |

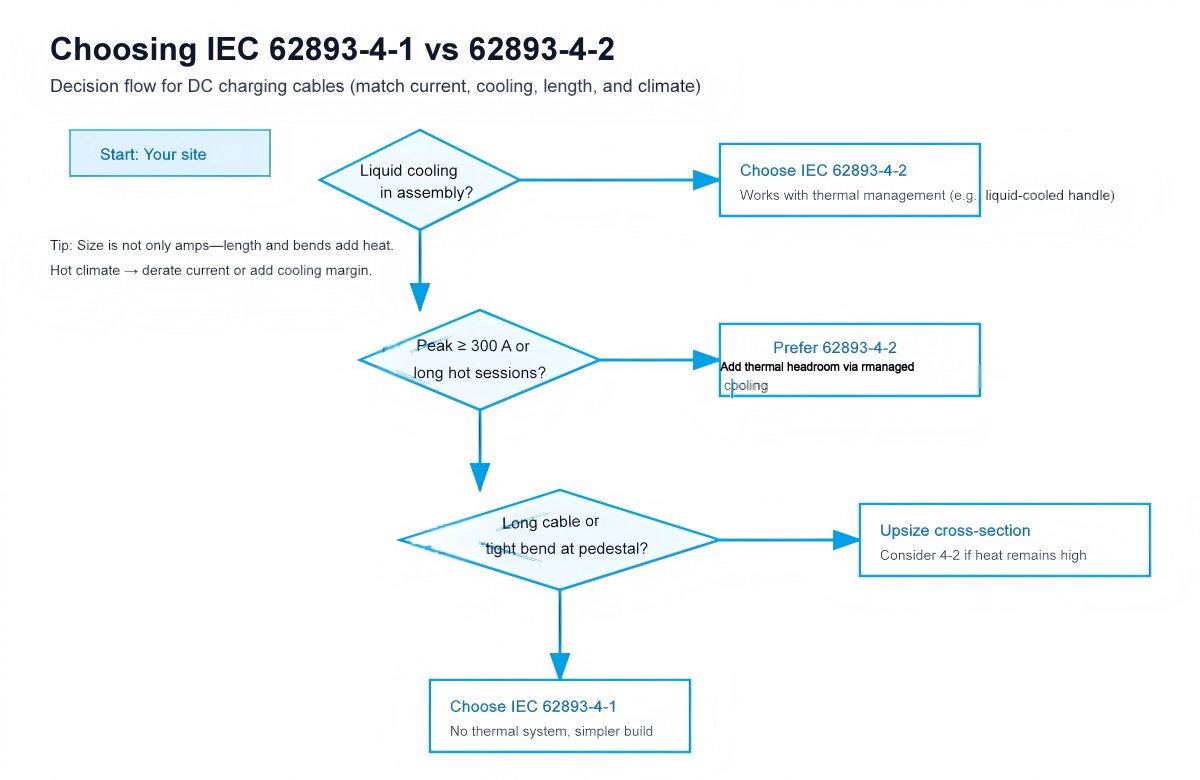

Choosing IEC 62893-4-1 vs IEC 62893-4-2

|

Situation |

Choose |

Why |

What to watch |

|

300–400 A peaks, long sessions, liquid-cooled handle |

62893-4-2 |

Works with thermal management in the assembly |

Coolant integrity, routing, and connector strain relief |

|

200–250 A, indoor depot, short cables |

62893-4-1 |

No thermal system, simpler build |

Afternoon back-to-back sessions; handle temperature rise |

|

Long cable runs or tight pedestals with frequent bends |

4-2 if liquid-cooled; otherwise size up 4-1 |

Extra length and bends increase heat |

Bend radius, torsion, and jacket scuff at the gland |

|

Hot climate with direct sun on the bay |

Often 4-2 with higher cross-section |

More thermal headroom |

UV exposure and derating policy |

How to run a 40-minute thermal trial at your site

1. Define the duty cycle

Peak current × minutes, average current × hours, sessions per day, ambient range.

2. Pick the test set

Select handle type, conductor size, cable length, and pedestal height that match your planned build.

3. Instrument the run

Log inlet and handle shell temperatures. Record current and ambient at 5-minute marks.

4. Run 40 minutes at your peak current

If you will duty-cycle, mirror your real pattern. Avoid artificial airflow.

5. Inspect after cool-down

Look at pins, latch, seals, backshell, cable gland, and first 50 cm of the jacket for scuff and twist.

6. Decide actions

If the handle rise or gland scuff is high, adjust conductor size, cable length, bend radius, or cooling set-points. Lock part numbers and the change-control path.

Pairing the handle and the cable: the quick checks

• Cross-section vs current: a longer or tightly routed cable needs more copper to hold the same current.

• Bend radius at the pedestal: tight turns near the gland heat the jacket and stress the conductors.

• Cable weight and reach: make sure operators can route it with one hand and gloves on.

• Cooling details (if used): protect coolant lines, clamps, and quick-connects from snag points; plan leak detection.

• Connector retention: test latch engagement with the cable hanging at typical reach.

Common pitfalls and fast fixes

• “We passed the standard, so it is fine.” → Run the site trial; lab points are not your microclimate.

• Cable too long to be “safe.” → Shorten the run or step up cross-section; add a hanger to reduce drag.

• Hot grips on summer peaks. → Improve airflow in the pedestal, raise conductor size, or move to a cooled assembly.

• Early jacket scuff at the gland. → Increase bend radius and add a fair-lead.

• Hard to service in the field. → Use parts with replaceable seals and accessible triggers; document torque values.

Ops and service notes

Stock the parts that actually wear: seals, triggers, and strain-relief kits. Time a real swap with basic tools and record the minutes. Build a simple change-control rule: when a supplier revises a connector or cable, you receive the new drawing, the new part number, and a summary of what changed. For teams that want to test a matched pair before rollout, consider pre-built connector-and-cable sets you can trial on site(Workersbee connector sets).

FAQ

What does IEC 62196-3 cover?

It defines DC vehicle connectors and inlets. The goal is safe, repeatable mating across brands at the interface.

What is IEC 62893-4-2 used for?

DC charging cables that work with a thermal management system in the assembly. It focuses on construction and endurance for that use.

Does a certificate guarantee lifetime at my site?

No. It proves performance under defined test points. Your climate, pedestal, and traffic pattern decide the real stress.

How do I know my cable size is enough?

Plot current vs time for a busy hour. If the handle or gland rise is high in the 40-minute trial, step up the cross-section or shorten the run.