Why liquid cooling is on the table

High current creates heat in conductors and at contact interfaces. If that heat isn’t carried away, temperatures rise, contact resistance worsens, and cables become heavy and stiff when you try to solve it with more copper. A closed liquid loop moves heat from the connector/cable to a radiator so power stays high and handling stays friendly.

Two routes in one view

Water-based (water–glycol)

High specific heat capacity and higher thermal conductivity. Excellent at bulk heat transport. Because water-glycol conducts electricity, it stays behind an insulated boundary; heat crosses through an interface into the coolant. Flow behavior in cold weather is generally predictable with the right mixture and materials.

Degradable synthetic oil

Intrinsically insulating, so some designs can bring it closer to hotspots. Specific heat and thermal conductivity are lower than water-glycol, so the system compensates via surface area, flow control, or duty-cycle management. Many oils thicken more at low temperatures; design for start-up and winter service.

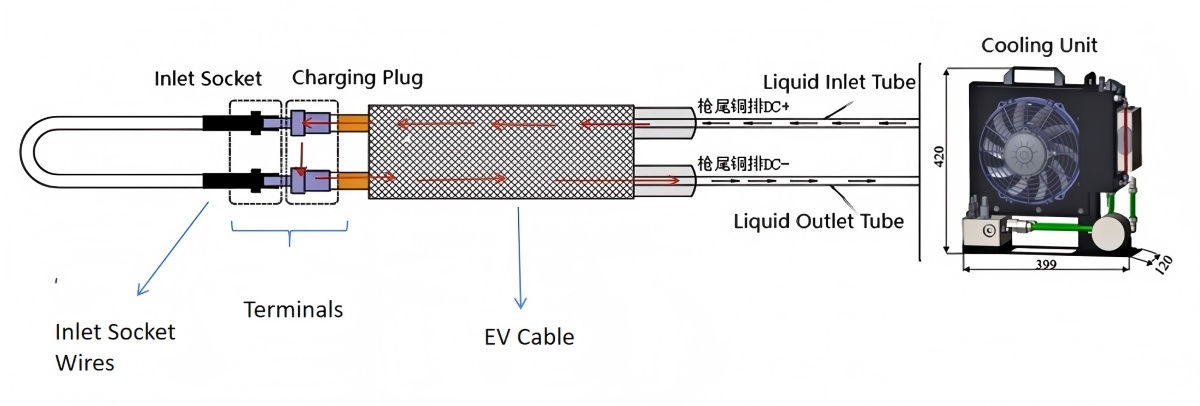

What’s inside the loop

Circulation unit with pump, radiator/fan, and reservoir → flexible lines routed through the cable and handle → sensors for liquid level, temperature, and pressure → station software that watches trends and raises alarms. Different cable lengths change flow resistance; longer runs need more pump head and careful routing.

Property snapshot

|

Property |

Water–Glycol (typical) |

Synthetic Cooling Oil (typical) |

What it means on site |

|

Specific heat (kJ/kg·K) |

~3.6–4.2 |

~1.8–2.2 |

Water-based moves more heat per kg per degree rise |

|

Thermal conductivity (W/m·K) |

~0.5–0.6 |

~0.13–0.2 |

Faster heat pickup on the water side for the same area |

|

Electrical behavior |

Conductive → needs insulated interface |

Insulating |

Oil can be closer to energized parts (still needs sound sealing) |

|

Low-temperature viscosity |

Moderate rise |

Often steeper rise |

Oil systems need more attention to cold-start flow |

|

Materials compatibility |

Metals, elastomers must suit glycol |

Metals, elastomers must suit oil |

Choose seals/hoses per coolant family |

How to choose: a simple path

Start from load, not headlines

Define the current range you’ll see most of the day (not the marketing peak), the typical session length, and whether sessions arrive back-to-back. This shapes the heat you must remove each minute, and the “recovery time” between sessions.

Map the climate and enclosure

Deep-cold regions push you to consider start-up viscosity, line routing, and warm-up behavior. Hot, dusty, or salty air demands unobstructed airflow and filter discipline at the radiator.

Decide how close the coolant can go

If you want the coolant very near hotspots, insulating oils simplify the electrical side; if you prefer a robust insulated boundary and maximum heat transport per liter, water-glycol is compelling.

Check pump head and line losses

Cable and hose length, bends, and quick-connects all add resistance. Ensure the pump can maintain target flow under that resistance. As a rule of thumb for high-current cables, designs commonly target several bar of available pump head; many systems for fast-charging cables operate around the high single-digit bar range to stay comfortable with longer paths and small-diameter passages.

Size the radiator by recovery, not only by peak

You’re designing for repeatability: stable temperatures across consecutive sessions. Pick cooling capacity so the system returns to a steady baseline fast enough for your site’s traffic pattern.

Scenario → focus → engineering move

|

Scenario |

What to watch |

Practical move |

|

Deep cold |

Start-up flow and bubbles |

Favor stable low-temp viscosity; design a smooth vent/fill; verify trend back to baseline |

|

Back-to-back sessions |

Heat accumulation and recovery |

Strengthen heat path and radiator margin; monitor time-to-baseline |

|

Dusty/salty air |

Radiator airflow, seals |

Keep intake/exhaust clear; routine filter cleaning; seal inspection |

|

Long cable runs |

Flow resistance, handling |

Gentle routing, stress relief, sensible bend radius; ensure pump head margin |

|

Tight cabinets |

Hot-air recirculation |

Duct hot air out; avoid recirculation into the intake |

Working example

A site runs many sessions at a high current level. Resistive losses in cables and contact interfaces turn into heat Q that must be removed by the loop.

The loop removes heat by raising coolant temperature across the cable segment and dumping it at the radiator.

If your average heat to remove is on the order of hundreds of watts to a few kilowatts (typical for high-power leads under sustained load), then at a 5–10 °C coolant rise you’re moving on the order of 0.02–0.2 kg/s of water-glycol. For oil, expect higher mass flow (or higher ΔT, or more area) to move the same heat because of lower specific heat and conductivity.

Longer hoses and tighter passages require more pump head to keep that flow. Plan pump head with margin so flow doesn’t collapse when filters load or lines age.

Monitoring that actually prevents downtime

Trend temperature, don’t just chase a threshold. A slow rise at the same load says the loop is getting “dirty” (minor seepage, air, filter loading, fan wear).

Watch level and pressure together. Stable level but falling pressure suggests restrictions; falling level with noisy pressure hints at air ingestion or seepage.

Instrument health matters. A tired fan or pump still “runs,” but the thermal curve will tell you it’s fading.

Alarm closure must be visible. It’s not an alarm until someone received it and acted.

Compliance as three lines of defense

Materials and geometry that keep coolant and conductors in their lanes → real-time sensing with redundancy for temperature/level/pressure → station alarms that reach responsible teams with a clear handoff to resolution.

Commissioning and routine care

Fill and vent the loop properly; confirm that temperature, level, and pressure read correctly in the station software; walk the hoses for rub points; keep contacts clean; log quick checks. Small routines prevent big problems.

Water vs oil

Choose water-glycol when bulk heat transport and predictable cold-weather flow are top priorities, and an insulated heat-exchange boundary fits your design philosophy.

Choose synthetic oil when electrical insulation at the coolant is strategically useful, you can design for cold-start viscosity, and you want closer proximity to hotspots without an extra insulated wall.

Key takeaways

Design for the current you actually deliver, the climate you live in, and the cadence of your traffic. Pick the coolant family that matches those realities, give the pump and radiator honest margins, and monitor trends. Do this well and fast charging stays quick, stable, and easy to handle—session after session.