Liquid-Cooled EV Charging Technology: Essential Advancements for High-Performance Charging Solutions

Liquid-Cooled EV Charging Technology: Essential Advancements for High-Performance Charging Solutions

Oct 30, 2024

In the evolving electric vehicle (EV) industry, advancements in charging technology are crucial to support faster, more efficient, and safer charging experiences. Liquid-cooled EV charging cables and connectors represent a vital leap forward, especially for high-power applications where traditional air-cooling methods cannot manage the heat generated. This article explores the technical principles, classifications, benefits, and testing requirements of liquid-cooled EV charging solutions, with insights from Workersbee’s expertise.

1. Understanding Liquid-Cooled EV Charging Technology

The primary advantage of liquid-cooled EV charging cables lies in their ability to maintain a stable temperature. A coolant circulates within the cable, dissipating the heat generated during high-power charging sessions. This approach enables the EV connectors and cables to handle greater current loads, crucial for modern fast-charging demands.

Key Coolants:

Liquid-cooled cables typically use two main types of coolants:

- **Water-Glycol Solutions:** These have a high specific heat capacity and a limited operational range (-30°C to 50°C). The solution circulates through the cable, transferring heat away from the conductors via thermally conductive materials.

- **Degradable Oil Options:** Options like Shell E4 and FUCHS 8025 provide good electrical insulation and interact directly with conductors without degrading rapidly, ensuring a long service life.

2. Classifications of Liquid-Cooled EV Connectors

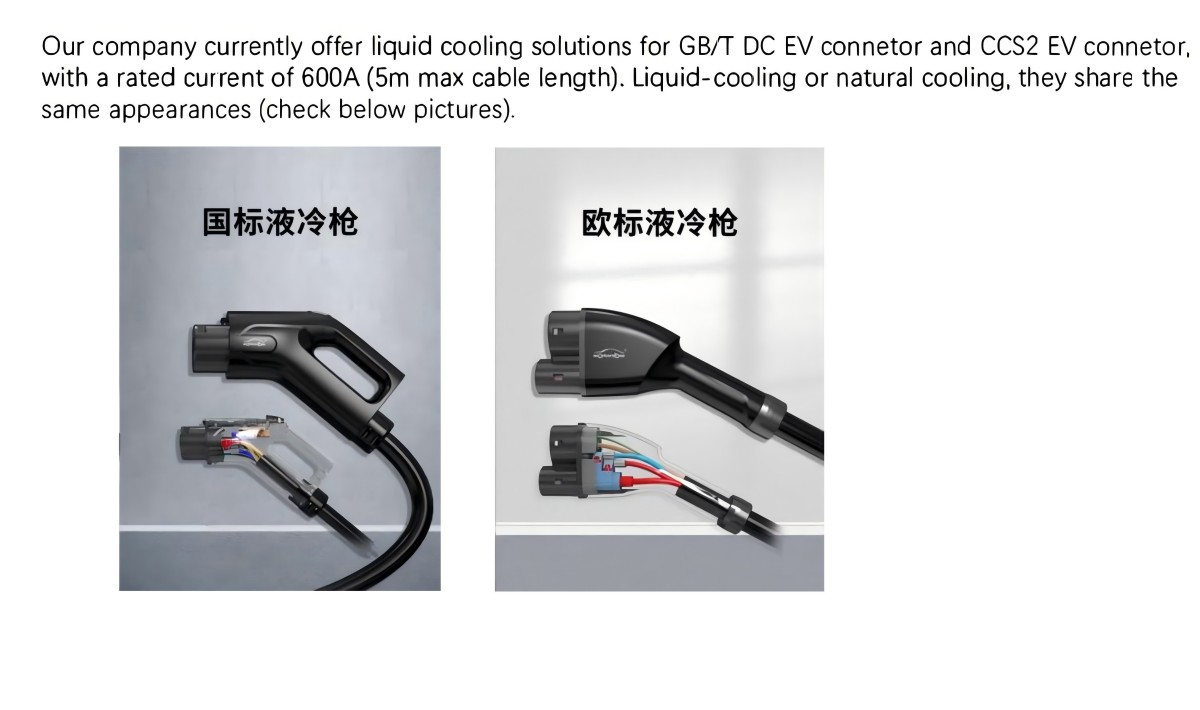

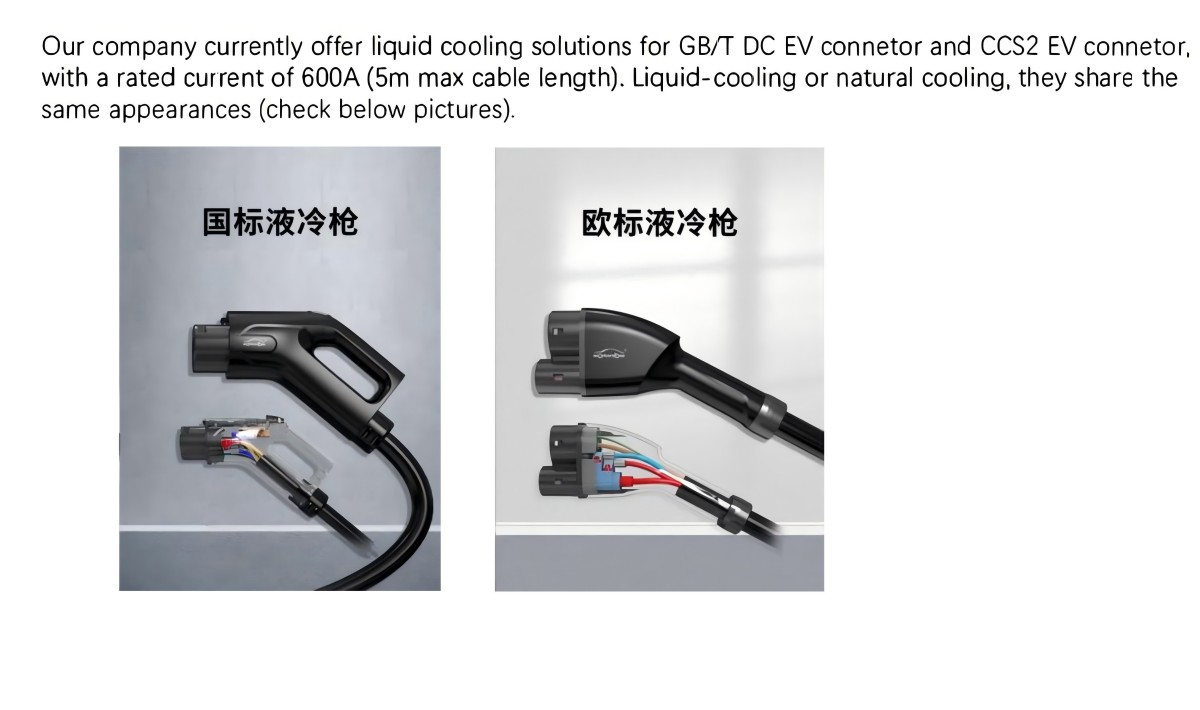

Workersbee's product line includes liquid-cooled solutions for different standards to meet the demands of various global markets:

- **GB/T Standard**: Commonly used in China, with a focus on DC-only charging and electronic lock mechanisms.

- **CCS2 Standard**: Widely adopted in Europe, this standard incorporates both AC and DC charging interfaces, catering to the diverse charging needs of European users.

- **NACS (Tesla)**: Tesla's proprietary standard that combines AC and DC functionality in a single connector design, optimizing charging for Tesla vehicles.

Each standard is engineered to handle the unique demands and regulatory requirements of its respective regions, ensuring compatibility and safety across diverse EV infrastructures.

3. Types of Liquid-Cooled Cable Structures

The design and effectiveness of a liquid-cooled EV charging cable hinge on its internal structure, which influences heat dissipation and mechanical resilience:

- **Immersed Structure**: In this design, the coolant directly contacts the copper conductor, enhancing cooling efficiency. However, the low-pressure requirements and larger tube sizes can limit flexibility.

- **Non-Immersed Structure**: Workersbee has opted for this structure, where the cooling tube is surrounded by copper wires. This design balances flexibility with safety, as coolant leaks are minimized and insulation is improved.

The non-immersed structure is especially advantageous for high-frequency use, as it provides robust mechanical resilience while maintaining optimal cooling efficiency.

4. Workersbee’s Innovations and Advantages

Workersbee’s liquid-cooled EV cables stand out due to several key engineering improvements:

- **Enhanced Cooling Tube Design**: The cables incorporate smaller 4.5/6mm cooling tubes, achieving a lower overall cable diameter and making the cables lighter and more flexible for easier handling.

- **Durability and Flexibility**: The cables have been tested to withstand significant physical stress, including a vehicle running over the cable, without compromising performance.

- **Advanced Coolants**: Workersbee's use of degradable oils ensures compatibility with regulatory standards, addressing environmental concerns and extending the lifespan of the cables.

- **High Safety Standards**: Workersbee minimizes risks associated with coolant leaks or conductivity issues by employing non-immersed structures and careful material selection.

5. Key Components of Liquid-Cooled EV Charging Cables

Liquid-Cooling Tubes

Workersbee’s cables use durable, high-performance materials like PTFE and FEP for cooling tubes. These materials withstand high temperatures and provide strong insulation, ensuring consistent cooling performance across various environmental conditions.

Connectors

The connectors used in liquid-cooled EV charging cables are crucial for a seamless charging experience. Workersbee utilizes quick-twist, quick-plug, and pagoda connectors that facilitate efficient coolant flow and self-sealing to prevent leaks during charging.

Sealing Systems

To prevent coolant leakage, the cables include high-performance sealing systems, ensuring that components like the plug, socket, and internal tubing remain airtight under high pressure. These systems are tested rigorously tomeet IP67 standards, which guarantee robust protection against environmental elements and operational wear.

6. Rigorous Testing for Reliability and Safety

For any liquid-cooled EV charging product, quality testing is crucial to ensure long-term reliability and safety. Workersbee conducts several tests to meet high-performance standards:

- **Temperature Rise Test**: This test measures how effectively the cable dissipates heat during charging. Workersbee’s cables consistently maintain a temperature rise below 50K, even during high-current charging.

- **Sealing Performance Tests**: Leakage can compromise cable safety, so Workersbee conducts multiple sealing tests, including airtightness and high-temperature operation tests, to ensure no coolant escapes during operation.

- **Short-Term Failure Simulation**: In this test, the coolant flow is temporarily stopped to simulate system failure. This ensures the cable assembly’s safety features are robust enough to prevent overheating in case of sudden coolant loss.

- **Mechanical Durability Tests**: Bending and compression tests are performed to assess the cable’s resilience to physical stress, simulating real-world scenarios where cables may be frequently bent or run over by vehicles.

7. Benefits of Liquid-Cooled Charging Technology

Adopting liquid-cooled charging technology brings significant advantages for both charging station operators and end-users:

- **Higher Charging Power**: Liquid-cooled cables support charging currents up to 600A, enabling faster charging sessions without overheating.

- **Cost-Effective Design**: The efficient heat dissipation allows for smaller conductor size, reducing material costs and making the cables easier to handle.

- **Enhanced User Experience**: The compact design and lightweight materials improve maneuverability, allowing users to plug and unplug with minimal effort.

- **Long-Term Durability**: With degradable coolant options and resilient material choices, liquid-cooled cables offer an extended operational lifespan, reducing replacement costs for station operators.

8. Workersbee’s Commitment to Future-Proof Solutions

Workersbee is dedicated to driving innovation in EV charging solutions. By offering liquid-cooled cables that meet or exceed global standards like GB/T and CCS2, Workersbee ensures that its products are compatible with current and future EV models. As the EV industry continues to grow, the demand for rapid, high-power charging solutions will rise, and liquid-cooled technology is set to be a cornerstone of next-generation EV infrastructure.

Conclusion: A Transformative Approach to EV Charging

Liquid-cooled EV charging cables are essential in enabling the transition to high-power charging solutions that meet the needs of today’s EV users. Workersbee's dedication to quality, safety, and performance in liquid-cooled technology ensures reliable, high-efficiency charging that benefits operators and users alike. By investing in liquid-cooled solutions, charging networks can support faster, more powerful charging, ensuring a seamless transition to the future of sustainable mobility.

Read More

What Are the Different Tesla Charging Connector Types?

What Are the Different Tesla Charging Connector Types?

NACS vs CCS2 (2025): Global Adoption, Regulations, and Connector Strategy

NACS vs CCS2 (2025): Global Adoption, Regulations, and Connector Strategy

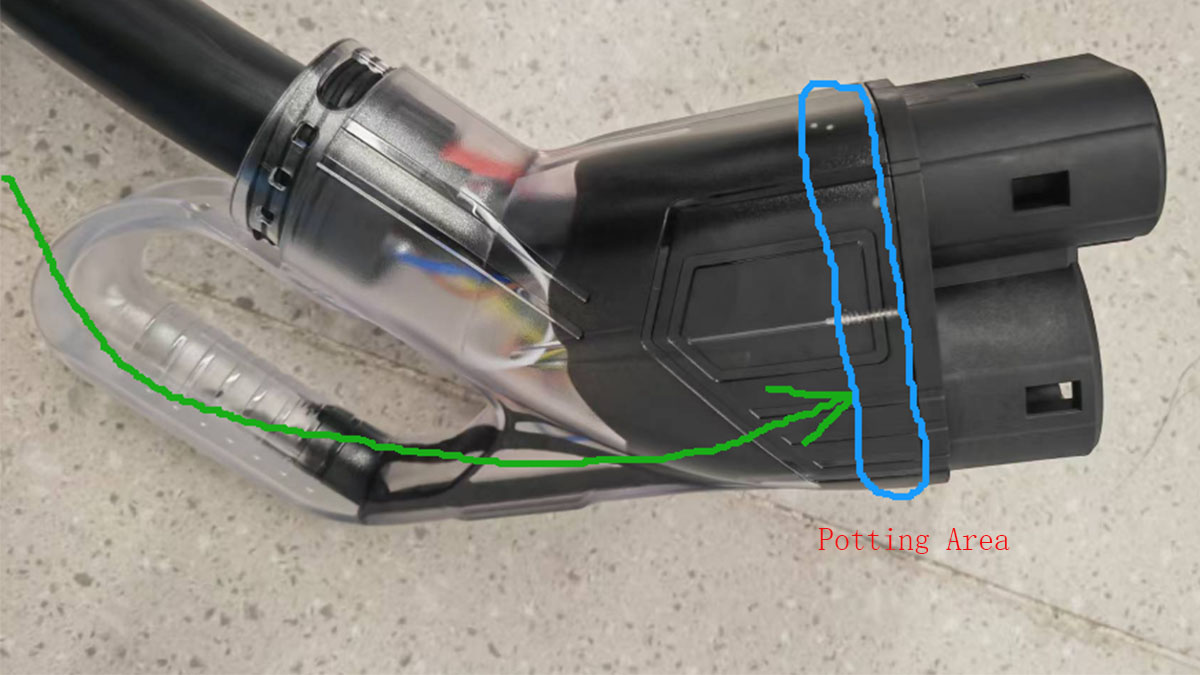

Why Potting the DC Connector Joint Matters | Workersbee

Why Potting the DC Connector Joint Matters | Workersbee

Liquid-Cooled EV Charging Technology: Essential Advancements for High-Performance Charging Solutions

Liquid-Cooled EV Charging Technology: Essential Advancements for High-Performance Charging Solutions