EV Connector Types Explained: 2025 Field Guide

EV Connector Types Explained: 2025 Field Guide

Aug 11, 2025

Most buyers and project teams ask the same three things: which connector fits my region, what charging power to expect, and how this choice affects installation. This guide walks through the mainstream EV connectors — Type 1, Type 2, CCS1, CCS2, NACS, GB/T, and CHAdeMO — with clear differences, typical use cases, and selection tips you can apply right away.

Quick Reference: Connector, Region, Typical Use

Connector

AC or DC

Typical field power

Primary regions

Common use

Type 1 (SAE J1772)

AC

Up to ~7.4 kW, single phase

North America, parts of Asia

Home and workplace charging

Type 2 (IEC 62196-2)

AC

Up to ~22 kW, three phase

Europe and many other regions

Public posts and residential wallboxes

CCS1

DC

Commonly 50–350 kW

North America

Highway and urban fast charging

CCS2

DC

Commonly 50–350 kW

Europe and many other regions

DC fast corridors and hubs

NACS (SAE J3400)

AC and DC in one port

Home AC + high power DC

Mainly North America, expanding

One port vehicle inlet

GB/T (AC and DC)

Both, separate interfaces

AC posts + high power DC

Mainland China

All scenarios in China

CHAdeMO

DC

Often around 50 kW at legacy sites

Japan and limited elsewhere

Older DC sites and fleets

AC vs DC at a Glance (typical ranges)

Mode

Voltage path

Who limits the power

Typical use

Level 1/2 AC

Grid → onboard charger → battery

Vehicle onboard charger

Homes, workplaces, long stay parking

DC fast charging

Grid → rectifier at station → battery

Vehicle battery/thermal limits and station design

Highways, retail hubs, depots

Type 1 (SAE J1772) — AC charging Takeaway: Simple single-phase AC used widely across North America for homes and workplaces.

What it is: A five pin AC connector. Real world setups often deliver up to about 7.4 kW depending on the circuit and the car’s onboard charger.

Where it fits: Residential wallboxes, portable chargers, and many workplace posts. Ideal where cars stay parked for hours.

Notes for projects: Confirm the onboard charger rating before promising charge times. For DC, most vehicles in this region use CCS1 on the same inlet.

Type 2 (IEC 62196-2) — AC charging Takeaway: Europe’s default AC connector, supporting single or three-phase; commonly up to ~22 kW on public posts.

What it is: A seven-pin AC design that works with single or three-phase supply. The connector remains the same regardless of phase.

Where it fits: Public posts, shared garages, residential wallboxes, and light fleet top ups.

Notes for projects: Cable choices matter—conductor size, jacket rating, and length affect heat, handling, and overall user experience. In these regions, DC fast charging typically uses CCS2, which keeps the Type 2 outline but adds dedicated DC pins.

CCS (Combined Charging System) — CCS1 and CCS2 are the main DC fast-charging interfaces. A single inlet on the vehicle supports AC and DC: CCS1 aligns with the Type 1 geometry, CCS2 with Type 2.

What it is: An AC shape combined with two DC pins. Field deployments commonly range from 50 to 350 kW. Higher power demands careful thermal management and cable selection.

Where it fits: Highway corridors, retail hubs, and depots that need quick turnarounds.

Notes for projects: A 350 kW dispenser does not guarantee a 350 kW session. Station capability, cable rating, ambient temperature, and the vehicle’s charging curve together define real outcomes. If high duty cycles are expected, consider liquid-cooled cable assemblies to reduce handle mass and keep temperatures in check.

NACS (SAE J3400) — one port for AC and DC Takeaway: Compact vehicle inlet that supports home AC and high-power DC in the same port.

What it is: A slim, ergonomic design favored for cable handling and packaging. Ecosystem coverage is expanding.

Where it fits: Homes, mixed-standard sites, and networks adding NACS alongside existing hardware.

Notes for projects: In mixed markets, verify vehicle compatibility, adapter policies, payment flow, and software support. Plan cable reach and strain-relief to protect the user experience as traffic grows.

GB/T — China uses separate connectors for AC and for DC, each designed specifically for its job.

What it is: AC serves homes, workplaces, and public posts; DC serves fast charging at service areas, city hubs, and logistics depots.

Where it fits: All passenger and many commercial scenarios in mainland China.

Notes for projects: Cross border travel requires adapter planning and awareness of local rules. For exports, vehicles often adopt alternate inlets to match destination markets.

CHAdeMO — an earlier DC standard that remains common in Japan and at a number of legacy sites elsewhere.

What it is: A DC connector that many older vehicles rely on; many sites target around 50 kW sessions.

Where it fits: Maintained networks in Japan, plus certain fleets and older installations in other regions.

Notes for projects: Outside Japan, availability is more limited than CCS or newer alternatives. Route planning is important if relying on these sites.

Selection Guide: How to pick the right connector

Region and compliance: Match the dominant regional standard first to cut adapters and support load. • Check certification and labeling requirements before procurement.

Vehicle mix: List inlets across current and near term fleets. • Consider visitors/tenants—mixed sites may justify dual standard posts.

Power target and dwell time: Long stay parking favors AC; quick turns and corridors favor DC. • Higher power increases cable mass and thermal demands—factor in ergonomics.

Site conditions — choose enclosure and impact protection to match local risks: temperature swings, dust or rain, and physical knocks. Use appropriate IP and IK ratings. • Use cable management to reduce wear, trips, and drops.

Operations and software: Payment and authentication must match user expectations. • OCPP integration and remote diagnostics reduce truck rolls.

Future-proofing: Size conduits and switchgear for later power increases. • Reserve space for liquid-cooled cables or additional dispensers if high power is on the roadmap.

Compatibility and Safety Checks: Adapters: Use certified units and follow local rules. Adapters do not increase charging speed. • Cables: Match connector rating, cable gauge, cooling method, and sealing to duty cycle and climate. • Inspection: Look for debris, bent pins, and worn seals; these are common causes of failed sessions. • Handling: Train staff on safe connection, emergency stops, and periodic cleaning.

Operator Playbooks (expandable)

Hardware layout: Consider dual-standard posts or swappable leads to serve CCS and NACS during transition periods. • Software flow: Ensure payment, authentication, and session data work consistently across connector families. • Cable ergonomics: Plan reach and strain-relief so a single bay serves varied inlet positions without stressing connectors.

ChaoJi aims to increase power delivery with a new mechanical and electrical interface. Where relevant, watch for compatibility pathways from existing standards. • V2X (vehicle-to-everything) depends on connector, protocol, and policy support. If bidirectional use is on your roadmap, confirm requirements early in design.

Use-Case Snapshots: Home and small business: AC wallboxes; prioritize cable length, tidy mounting, and a clear display. • Workplaces and destinations: Mix of AC for long stays and a limited number of DC posts for quick turns. • Highways and depots: DC first; design for queueing, cable reach, and quick recovery from connector damage.

Mini Glossary: AC charging: Power is rectified inside the vehicle by the onboard charger. • DC fast charging: Power is rectified at the station and delivered directly to the battery. • Vehicle inlet vs plug: The inlet is on the car; the plug is on the cable or dispenser. • Single vs three-phase: Three phase enables higher AC power at suitable sites. • Liquid-cooled cable: A high-power DC cable with coolant channels that reduce handle mass and heat.

FAQ

Is Type 2 the same as CCS2?

No. Type 2 is an AC connector. CCS2 builds on the Type 2 geometry, integrating extra DC contacts for high-rate charging.

Can NACS and CCS coexist on the same site?

Yes. Many operators deploy mixed hardware or support adapters where permitted. Confirm policies and software support.

How fast is AC compared with DC?

AC power is limited by the onboard charger in the car, so it suits long dwell times. DC bypasses the onboard charger and usually delivers much higher power for short stops.

Do adapters change my maximum charging speed?

No. The vehicle, cable rating, and station design set the ceiling. Adapters mainly provide physical compatibility.

What should I check before choosing cables and connectors?

Confirm target power, duty cycle, ambient conditions, and handling needs. Match connector rating, cable gauge, cooling method, and sealing accordingly.

Explore connectors by standard:

• Type 1 AC plug & cable• Type 2 AC charging cable• CCS1 DC plug (200A)• CCS2 DC plug (Gen 1.1, 375A natural-cooled)• Liquid-cooled CCS2 solutions• NACS connector• GB/T AC connector• GB/T DC connector• EV connector category overview

Related testing & engineering reads:

• Liquid-cooled EV charging technology• Salt-spray & durability testing

Read More

Three-Phase Portable Charging at Home: Choosing Between Workersbee Dura Charger and ePort C

Three-Phase Portable Charging at Home: Choosing Between Workersbee Dura Charger and ePort C

How IP Ratings Affect EV Connector Durability

How IP Ratings Affect EV Connector Durability

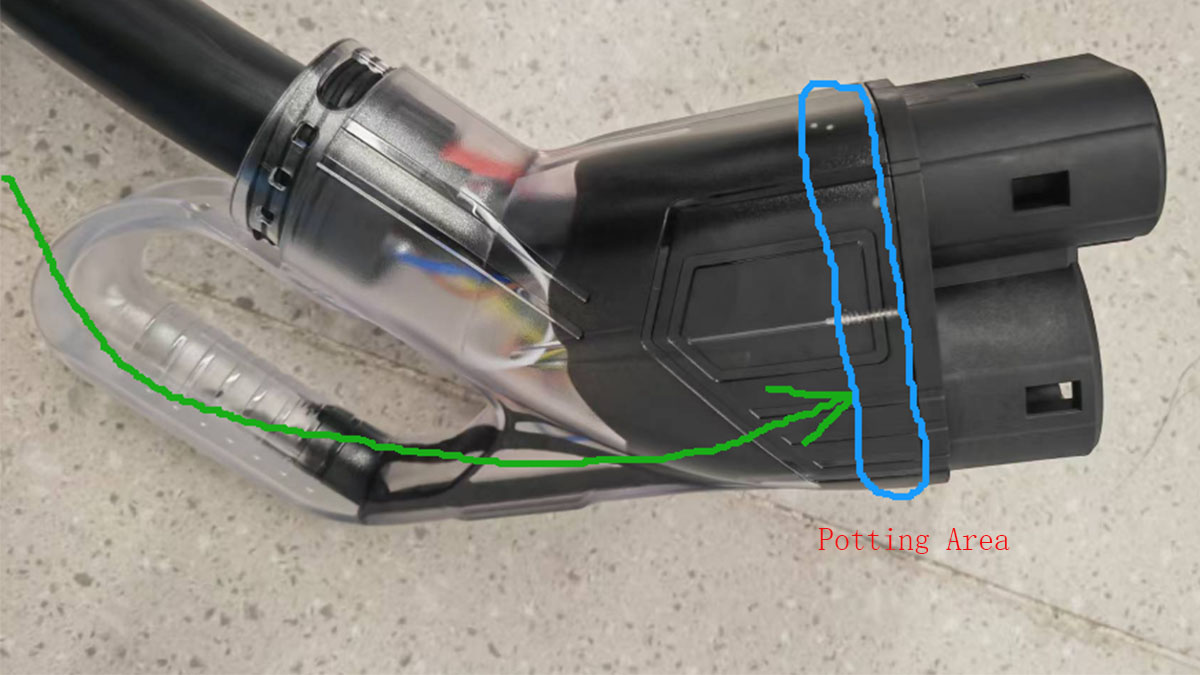

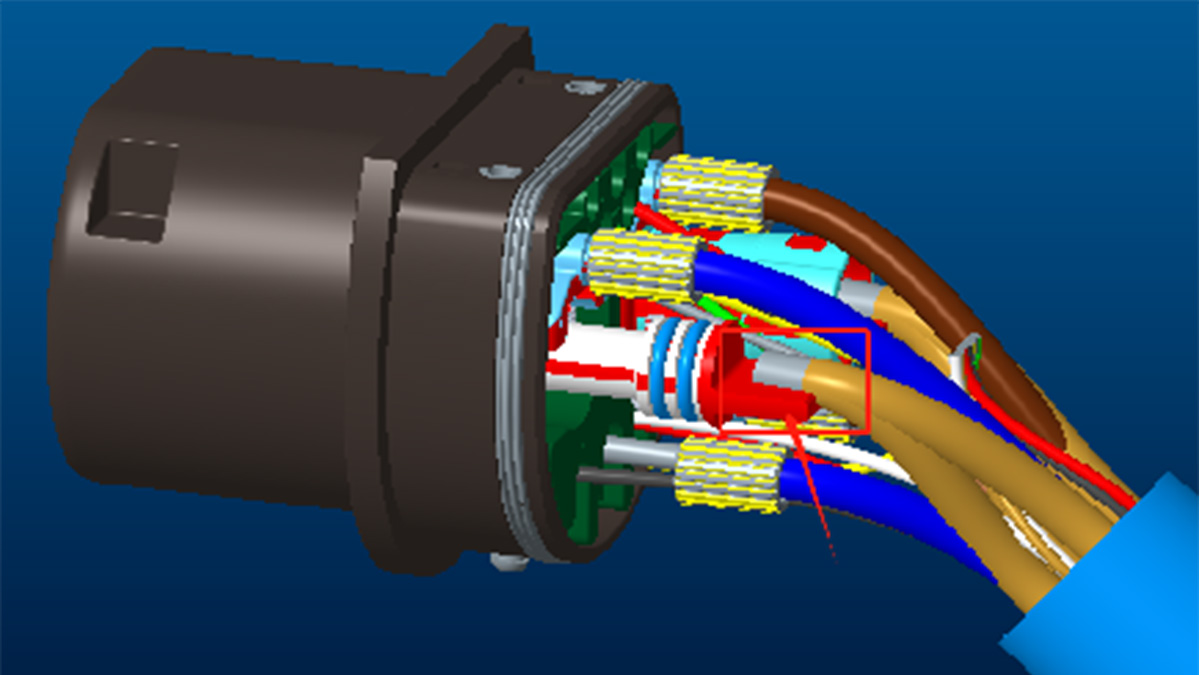

Why Potting the DC Connector Joint Matters | Workersbee

Why Potting the DC Connector Joint Matters | Workersbee

EV Connector Types Explained: 2025 Field Guide

EV Connector Types Explained: 2025 Field Guide

EV Charging Connector Compatibility Issues: Causes and Fixes Explained

EV Charging Connector Compatibility Issues: Causes and Fixes Explained

Why Workersbee's EV Charging Connectors Use Temperature Sensors for Safer Charging

Why Workersbee's EV Charging Connectors Use Temperature Sensors for Safer Charging

How to Select a Durable DC Charging Connector for Harsh Outdoor Conditions

How to Select a Durable DC Charging Connector for Harsh Outdoor Conditions

375A Naturally-Cooled CCS2 EV Charging Cable for Public DC Fast-Charging | Workersbee

375A Naturally-Cooled CCS2 EV Charging Cable for Public DC Fast-Charging | Workersbee

Workersbee Dura Charger: The Ultimate Portable & Multifunctional EV Charging Solution

Workersbee Dura Charger: The Ultimate Portable & Multifunctional EV Charging Solution

Why Liquid Cooling Is the Future of High-Power EV Chargers (2025 Guide)

Why Liquid Cooling Is the Future of High-Power EV Chargers (2025 Guide)

Do EV Chargers Really Need an LCD Screen?

Do EV Chargers Really Need an LCD Screen?

Practical Guide to EV Extension Cable Adapters in 2025: Solving Distance and Compatibility Issues

Practical Guide to EV Extension Cable Adapters in 2025: Solving Distance and Compatibility Issues