A new study from the University of Washington puts hard numbers behind a familiar curbside truth: perception of public-charging reliability can make or break the decision to buy an EV. One awkward session—payment loops, cryptic error messages, a plug that needs reseating, or a sudden power drop—can outweigh months of positive messaging and sour a driver on a whole location.

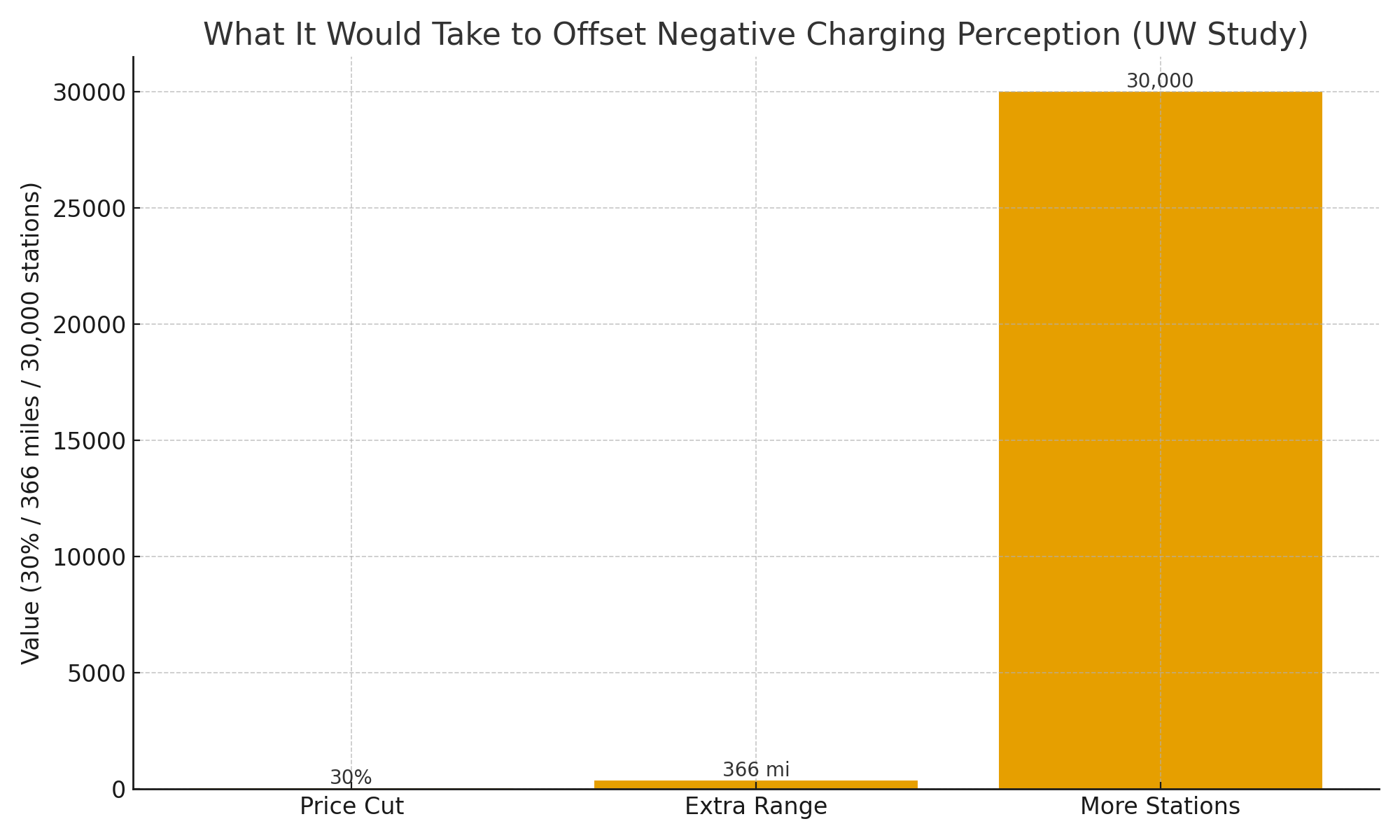

Crucially, the researchers quantify how hard it is to “offset” a negative view of public charging. In their scenario analysis, it would take a 30% vehicle price cut, or +366 miles of extra range, or 30,000 additional public charging stations nationwide to counteract poor reliability perception. That’s a stark reminder: adoption doesn’t hinge on specs alone; it hinges on confidence at the curb.

Why does perception lag even as reported uptime improves? Because confidence is formed in the first seconds of a session. The connector should seat with a clear click. Payment should start on the first try. Current should hold steady under load. If any of those steps stumble, most drivers won’t investigate root causes—they’ll remember the site as unreliable and avoid it.

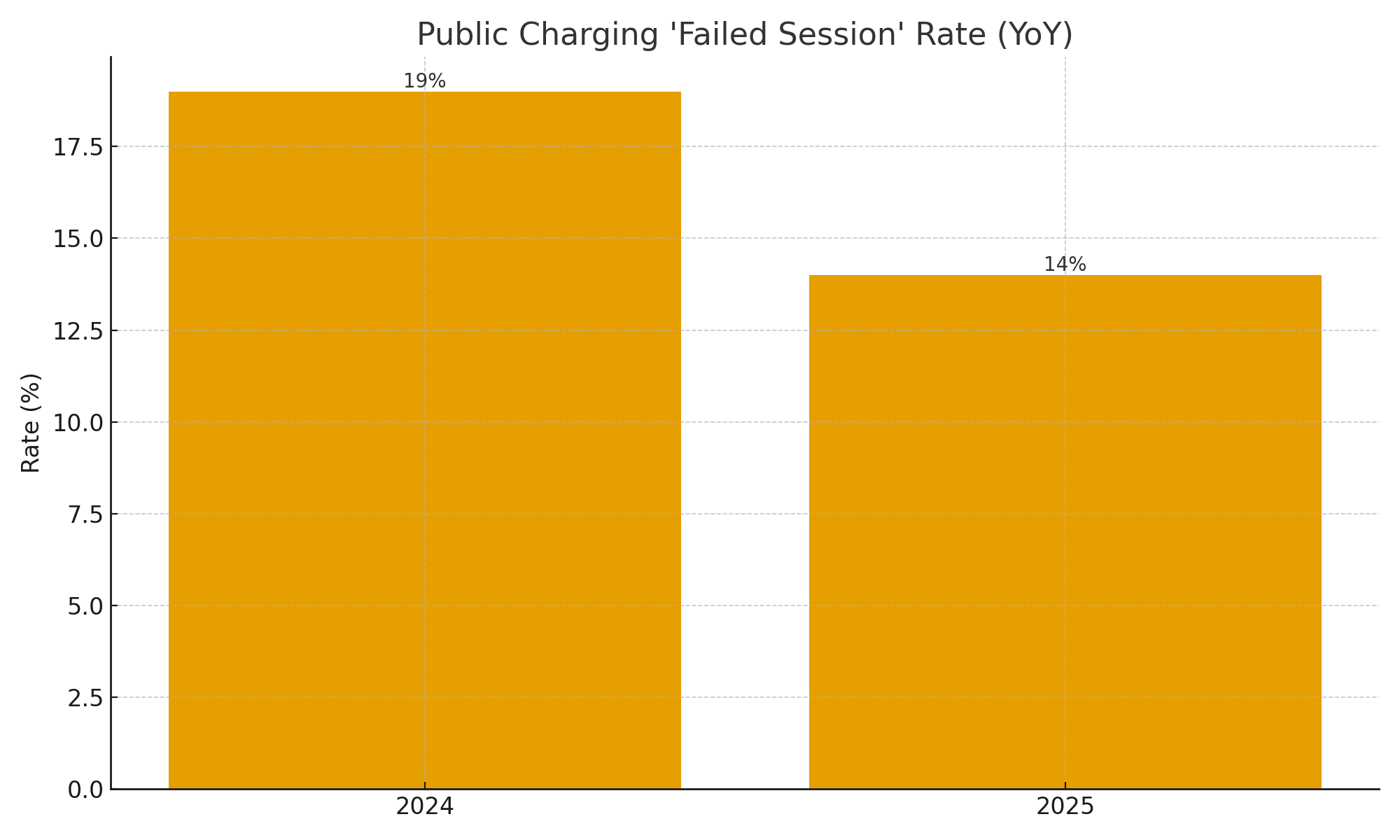

Industry tracking supports the gap between metrics and lived experience. Over the past year, the share of failed charging attempts at public sites improved from 19% to 14%, yet overall satisfaction still slipped, largely due to payment friction and cost perception. Objective reliability is trending up, but felt reliability still needs work.

For operators, the takeaway is practical:

Treat first-attempt success as a primary KPI alongside uptime and repair times. Measure the full path—plug in, pay, reach stable power—without driver intervention.

Keep payment redundancy truly independent (for example, card + QR/app with an offline fallback) so weak connectivity doesn’t end a visit.

Reduce avoidable thermal derates. Handle-level temperature sensing and low contact resistance prevent “mystery slowdowns” that feel like failure. Where high current is routine, liquid-cooled assemblies keep delivery steady without forcing drivers to fight heavy cables.

Close the loop from alarm to verified fix, and only then bring a bay back online. Plain-language screens that explain issues and suggest next steps turn a bad moment into a manageable detour.

From a supplier perspective, this is where design choices meet operations. Workersbee focuses on connector ergonomics, clear mechanical feedback, accessible components for fast field service, and—where duty cycles demand it—liquid-cooled CCS2 options engineered to hold current steady at the handle with low noise. These details turn reliability into something drivers can feel.

Editor’s note on sources: The University of Washington study provides the scenario results cited above (30% price, +366 miles, +30,000 stations). Industry tracking indicates the year-over-year drop in failed sessions from 19% to 14%, while overall satisfaction softened due to payment and cost factors.