summary

– Continuous 375–400 A delivery without a liquid loop, validated by third-party thermal tests using a 50 K temperature-rise limit

– Short-duration headroom to 450–500 A under controlled duty cycles and ambient conditions

– Lower system complexity and maintenance versus liquid-cooled assemblies, ideal for highways, urban hubs, and fleet depots

Introduction

High current is easy to claim and hard to sustain. For operators, the real question is whether a cable can hold its temperature within a predictable window long enough to serve the typical session mix at your site.

Workersbee’s naturally-cooled CCS2 cable targets the 375–400 A band for day-to-day operation and provides short bursts to 450–500 A, depending on ambient temperature and duty cycle. The result is strong throughput without the pumps, hoses, coolant, or extra service tasks that come with active cooling.

Quick specifications

(The table collates what buyers ask first so they can qualify the solution in minutes.)

|

Parameter |

Value / Notes |

|

Interface |

CCS2 (IEC 62196-3 configuration) |

|

Continuous current class |

375–400 A, verified against a 50 K conductor/terminal ΔT criterion |

|

Short-duration overload |

Up to 450–500 A for limited intervals under defined duty cycles |

|

Conductor layout |

Multi-core copper, example build 4 × 60 mm² for DC paths plus control cores |

|

Thermal control |

Passive (no liquid loop, no fans) |

|

Typical use cases |

Motorways and urban fast chargers, fleet depots, mixed-use public hubs |

|

Operating temperature |

Site-dependent; derating guidance provided below |

|

Ingress protection |

Determined by the mated gun and inlet assembly; follow handle/inlet datasheets |

|

Compliance intent |

Designed to meet applicable IEC requirements; third-party test summary available |

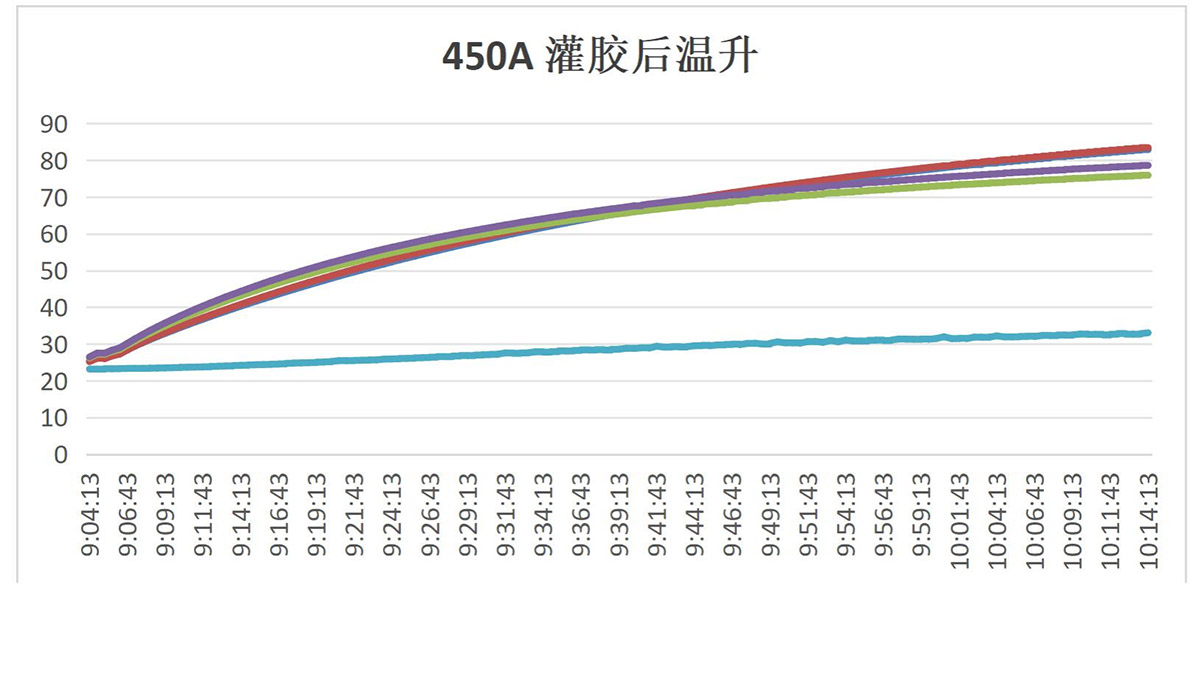

Independent thermal testing at a glance

A third-party laboratory performed stepped-current runs at warm-weather ambients (roughly high-20s to low-30s °C). The pass/fail yardstick was a temperature-rise limit of 50 K at the critical points. The cable held within the limit throughout the 375–400 A band and offered controlled, short-duration operation at 450–500 A.

In practice, this means a naturally-cooled build can complete most real-world sessions in the target current range without an active loop. For procurement traceability, publish the lab name, report ID, and test date alongside a downloadable summary on the page.

What the results mean for operators

– Throughput: Fewer thermal throttles in typical warm conditions at 375–400 A, so queues shorten and sessions complete more predictably.

– Simplicity: No pumps, fans, sensors for a liquid loop, or coolant top-ups, reducing points of failure and truck rolls.

– TCO: Lower capex and service line items versus liquid-cooled assemblies in this current class.

Where a naturally-cooled cable fits best

– Highways with steady 15–25-minute sessions from mid-SOC

– Urban sites with moderate dwell and high turnover

– Fleet depots with planned charging windows and known duty cycles

When to prefer liquid-cooled

– Ultra-high currents sustained for long windows in hot climates

– Design envelopes that require very small cross-sections and tight bend radii at extreme power levels

Derating and duty-cycle guidance

Thermal headroom shifts with ambient temperature, airflow around the cable and gun, and session profile. As a simple rule of thumb for engineering reviews: above 35–40 °C ambient, plan for shorter high-current plateaus or for slightly lower setpoints to keep ΔT within the 50 K limit. For fleets, simulate a day’s duty cycle and check that cumulative heat from back-to-back sessions still leaves recovery time.

Naturally-cooled vs liquid-cooled vs forced-air

(Use this as a quick scoping aid during RFPs and site design.)

|

Aspect |

Naturally-cooled cable |

Liquid-cooled cable |

Forced-air assisted |

|

Continuous current window |

375–400 A typical |

500 A and above sustained |

300–400 A typical |

|

System complexity |

Low; no loop components |

High; pumps, hoses, coolant, seals |

Medium; fans, ducts, filters |

|

Service items |

Visual checks, torque/strain relief, sleeve wear |

Coolant checks, pump life, leak tests |

Fan/filter replacement, noise checks |

|

Failure modes |

Mechanical wear only |

Leaks, pump failure, connector fouling |

Fan failure, dust ingress |

|

Ambient sensitivity |

Moderate |

Lower for same current |

Moderate to high |

|

Noise |

Silent |

Silent |

Audible |

|

Best fit |

High-volume public/fleet in warm to hot climates |

Ultra-fast lanes, extreme duty sites |

Budget upgrades and retrofits |

Applicable standards and references

This cable family is engineered with the following frameworks in mind. Use precise editions as required by your market and certifier.

– IEC 62196-3 for DC vehicle couplers (CCS2 configuration)

– IEC 61851-23 and -24 for DC EVSE and communication

– IEC 62893 series for EV cable assemblies

– IEC 60529 for ingress protection ratings as declared on the mated gun/inlet

– Local conformity regimes such as CE, UKCA, or national marks where applicable

Installation and maintenance checklist

– Match the cable cross-section and gun to the cabinet’s rated current and duty cycle

– Respect minimum bend radius and strain-relief instructions during routing

– Keep sleeves and seals clean; remove conductive dusts and road grime

– Inspect terminals periodically for torque and discoloration

– In hot seasons, verify that charging profiles still sit inside the intended temperature-rise window

Frequently asked questions

Q. What does the 50 K temperature-rise limit represent

A. It is a commonly used thermal criterion in cable and connector evaluation. The assembly is exercised at current while the temperature increase at defined points must stay within 50 K above ambient.

Q. Can a naturally-cooled cable hold 400 A in very hot weather

A. Yes in many cases, as shown by third-party tests. At higher ambients, duty cycle and airflow matter. Operators can trim current slightly or reduce plateau duration to preserve margin.

Q. Is a temperature sensor required

A. A naturally-cooled cable does not use a liquid loop or fan control. Basic safety monitoring on the handle and terminals remains part of good design practice and should be kept.

Q. How do I choose a matching inlet/socket

A. Pair the gun and inlet for the same current class and conductor cross-section. For the tests referenced here, the assembly was matched to a heavy-gauge socket; your selection should follow the site’s rated current and connector spec.

Q. When should I move to liquid-cooled

A. If your site needs long, repeated high-current plateaus above this cable’s continuous band in hot climates, or if space constraints dictate smaller cross-sections at very high power.

Contact us for:

Get the datasheet

Request the third-party thermal test summary

Talk to an engineer about duty-cycle sizing

Discounted samples for testing