Safety Standards for EV Connectors in Different Regions

Safety Standards for EV Connectors in Different Regions

Sep 26, 2025

Safety is more than a plug that fits. For EV connectors, it blends three layers: electrical safety, functional safety, and connected-system security. Standards define how to build and test. Regulations decide what can be sold or installed. Procurement needs both in view, or uptime becomes guesswork.

Regional quick reference

Region

Common connectors

Core safety standards (examples)

Regulatory / conformity themes

Notes for buyers

North America (US/CA)

J1772 (AC), CCS1 (DC), J3400

UL 2251 for connectors/couplers; UL 2594 for AC EVSE; UL 2202 for DC; UL 9741 for V2X; install per NEC 625

Funding rules and utility interconnect; accessibility and uptime language in tenders

Ask for NRTL listings, temperature-rise data, HVIL tests, cable strain evidence, and label photos

European Union / UK

Type 2 (AC), CCS2 (DC)

EN/IEC 62196 for connectors; EN/IEC 61851 for EVSE; EMC/LVD as applicable

AFIR for public networks; security obligations for connected gear; payment and price transparency

Look for a Declaration of Conformity with harmonized EN standards and security documentation for connected features

China (Mainland)

GB/T AC/DC; ChaoJi pathway emerging

GB/T 20234.x interfaces; GB/T 27930 communication

Domestic certification schemes and grid rules

Check edition years on GB/T certificates; verify comms conformance and pin temperature-rise results

Japan

CHAdeMO (DC), Type 1 (AC in legacy)

JEVS/CHAdeMO documents for DC; national electrical and EMC frameworks

Collaboration with ChaoJi pilots; local approvals for public sites

Confirm CHAdeMO certification and CAN messaging conformance

India

CCS2 (new public DC), legacy Bharat AC/DC

IS 17017 series based on IEC 61851/62196

BIS certification; DISCOM interconnect terms

Ask for BIS marks, enclosure IP evidence, ambient derating policy, and spare-parts plan

What the tests actually cover• Insulation, creepage, and clearance to limit arcing• Temperature rise on pins, terminals, and cable conductors at stated currents• Ground continuity and protective bonding• Mechanical integrity: drop, impact, latch durability, mating cycles• Environmental protection: IP rating, corrosion, UV aging, salt fog• Functional interlocks (HVIL), latch detection, safe de-energization before unmating• Material safety: flammability, tracking resistance, thermal indexes• For connected equipment: secure updates, credential policies, incident handling, and anti-fraud controls where payments exist

North AmericaPublic DC sites support CCS1 and, in many places, J3400 alongside it. Safety relies on the UL family. Inspect listing scopes for the exact connector and EVSE variants. Request temperature-rise curves at the currents and ambients you expect, not just a single point. Installation follows NEC 625 and local code. In tenders, uptime and payment access show up; pick connectors that expose readable sensors and have wear parts you can swap fast.

European Union and UKType 2 rules AC; CCS2 is standard for DC. EN/IEC 62196 and 61851 frame connector and EVSE safety. Treat security as part of safety if the product is connected: evidence for secure updates, credential rules, and user guidance matters. AFIR raises the bar on interoperability and payment clarity. Confirm the Declaration of Conformity cites the right harmonized standards and edition years. Make sure device identifiers and logs are accessible for audits.

ChinaGB/T 20234 defines the physical interfaces; GB/T 27930 aligns communication. Check that certificates match current editions and the purchased variant. Cable length and cross-section influence temperature rise, so match the tested configuration. If ChaoJi is on the roadmap, validate the mechanical, thermal, and handling path early, including cooling approach and cable mass.

JapanCHAdeMO remains central in many deployments. Verify certification currency, CAN messaging behavior, and cycle life. Where projects touch ChaoJi pilots, agree on adapter or migration steps and how site labeling will guide drivers during transition.

IndiaRollouts favor CCS2 for public DC; Bharat formats remain in legacy fleets. IS 17017 maps closely to IEC, but BIS marks and local utility approvals are required. Hot ambient and dust justify a closer look at derating and IP performance. In dense areas, confirm reach and strain relief around tight parking.

Recent changes (2024–2025)• North America: J3400 (standardized NACS) grows alongside CCS1; UL family remains the safety anchor; installation references NEC 625.• European Union/UK: beyond EN/IEC 62196 and 61851, connected products face security obligations under radio/cyber provisions; AFIR strengthens interoperability and payment clarity for public networks.• China: GB/T 20234 and GB/T 27930 editions have been updated; align certificates with current versions and with the purchased cable set; ChaoJi programs continue to advance.• India: IS 17017 aligns to IEC for new deployments; BIS certification and local utility approvals remain mandatory; CCS2 dominates new public DC.• Japan: CHAdeMO certification and CAN behavior remain central; collaboration paths with ChaoJi exist in pilots.

What counts as proof of conformity

• Certificates or listings that name the purchased variant, with edition years and model codes.• Summaries of critical tests: pin and terminal temperature-rise across ambient bands, dielectric strength, HVIL behavior, enclosure IP.• Label proofs: rating plate artwork or photos with serials/traceability and required warnings.• For connected equipment: a security note describing update and rollback processes, credential policy, and audit-log availability.

Safety standards get products admitted to the market; regional regulations decide how they are deployed; real-world performance still depends on matching the certified product to the site conditions. Keep the regional map in view, verify the edition years on certificates, and read the temperature-rise and HVIL data alongside your ambient and duty cycle.

FAQ

What’s the difference between standards and regulations for EV connectors?A: Standards (for example, IEC 62196/61851, UL 2251/2594) define how connectors and EVSE are designed and tested—dimensions, insulation, temperature-rise, interlocks, EMC. Regulations and codes (for example, AFIR in the EU, national radio/cyber provisions for connected gear, NEC 625 for installation in the US) decide what can be marketed, installed, and how it must behave in public networks. Certification/listing shows a product was tested to a specific edition of a standard; regulatory conformity shows it is legally deployable in that region.

Which connector families are used by region?A: North America uses J1772 for AC, CCS1 for DC, with J3400 growing alongside. The EU/UK use Type 2 for AC and CCS2 for DC. China uses GB/T (with a path toward ChaoJi in some programs). Japan uses CHAdeMO for DC and Type 1 in legacy AC contexts. India’s new public DC largely adopts CCS2, while some fleets still operate Bharat AC/DC formats.

What test results matter most on a datasheet or report?A: Prioritize temperature-rise at the pins/terminals across your ambient band (ask for the curve, not a single point), dielectric withstand, HVIL behavior and safe de-energization, enclosure IP rating, and mechanical cycle life of the latch/trigger. For connected equipment, ask how firmware is signed and updated, whether rollback is supported, and how audit logs can be exported. Label clarity (ratings, warnings, serials) is part of safety evidence—keep photos on file.

How can I verify conformity beyond seeing a certificate?A: Match model codes and options on the certificate to the exact variant you will buy (including cable length/cross-section). Check the edition years of the cited standards. Request label artwork or photos and a short summary of critical tests (temperature-rise, HVIL, IP). Run a brief on-site trial with several heavy sessions at target current and record temperatures and any derates. For connected units, request a security note that explains update and credential policies and confirms log export for audits.

Read More

How to Choose the Right Portable EV Charger for Your Business

How to Choose the Right Portable EV Charger for Your Business

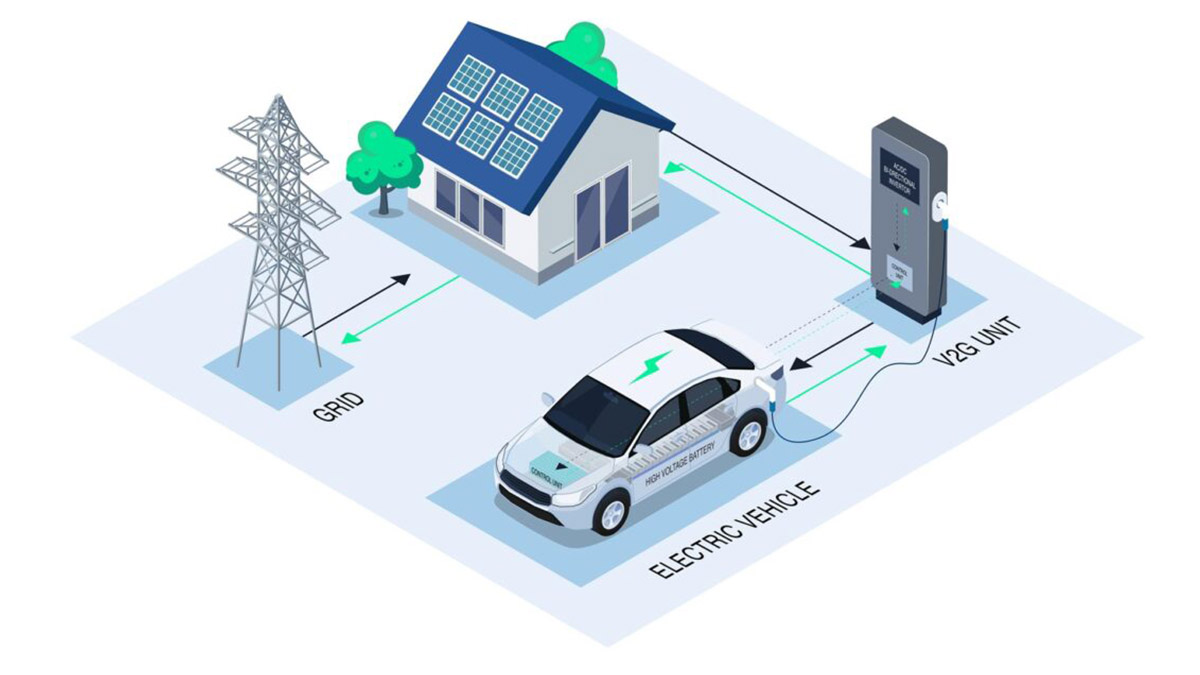

V2X Basics: How EVs Can Power Homes, Buildings and the Grid

V2X Basics: How EVs Can Power Homes, Buildings and the Grid

Safety Standards for EV Connectors in Different Regions

Safety Standards for EV Connectors in Different Regions

EV Connector Selection for Public and Private Sites 2025

EV Connector Selection for Public and Private Sites 2025

IEC 62196-3 and IEC 62893-4-2 Explained: What Certifications Really Prove

IEC 62196-3 and IEC 62893-4-2 Explained: What Certifications Really Prove

Can You Get Portable Electric Car Chargers? A Complete Guide in 2025

Can You Get Portable Electric Car Chargers? A Complete Guide in 2025

AFIR 2025: CCS2 DC Charging Compliance & Site Playbook (EU)

AFIR 2025: CCS2 DC Charging Compliance & Site Playbook (EU)

NACS vs CCS2 (2025): Global Adoption, Regulations, and Connector Strategy

NACS vs CCS2 (2025): Global Adoption, Regulations, and Connector Strategy

Portable EV Charger Guide Level 1 vs Level 2, Mobile Units, Safety

Portable EV Charger Guide Level 1 vs Level 2, Mobile Units, Safety

Choosing the Right EV Connector for Your Charging Station (2025 Guide)

Choosing the Right EV Connector for Your Charging Station (2025 Guide)

Europe's EV Charging Market in 2025: Trends, Insights, and Opportunities

Europe's EV Charging Market in 2025: Trends, Insights, and Opportunities

EV Charging Stations: A Growing Investment Opportunity in the Green Transportation Revolution

EV Charging Stations: A Growing Investment Opportunity in the Green Transportation Revolution