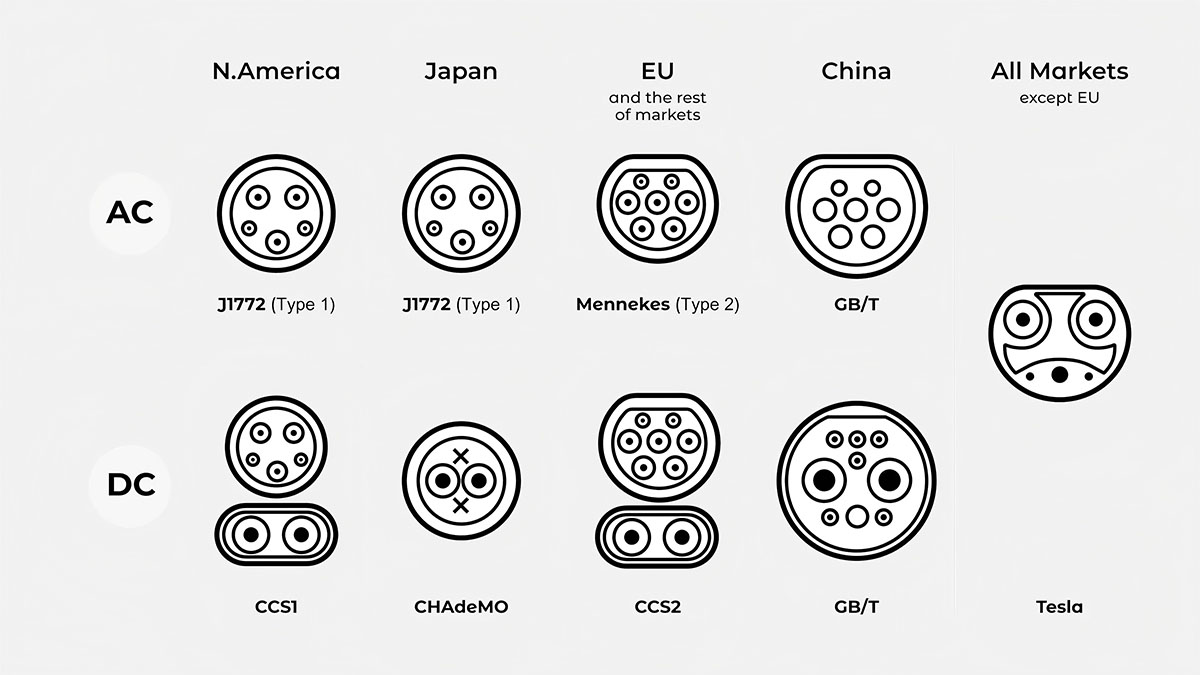

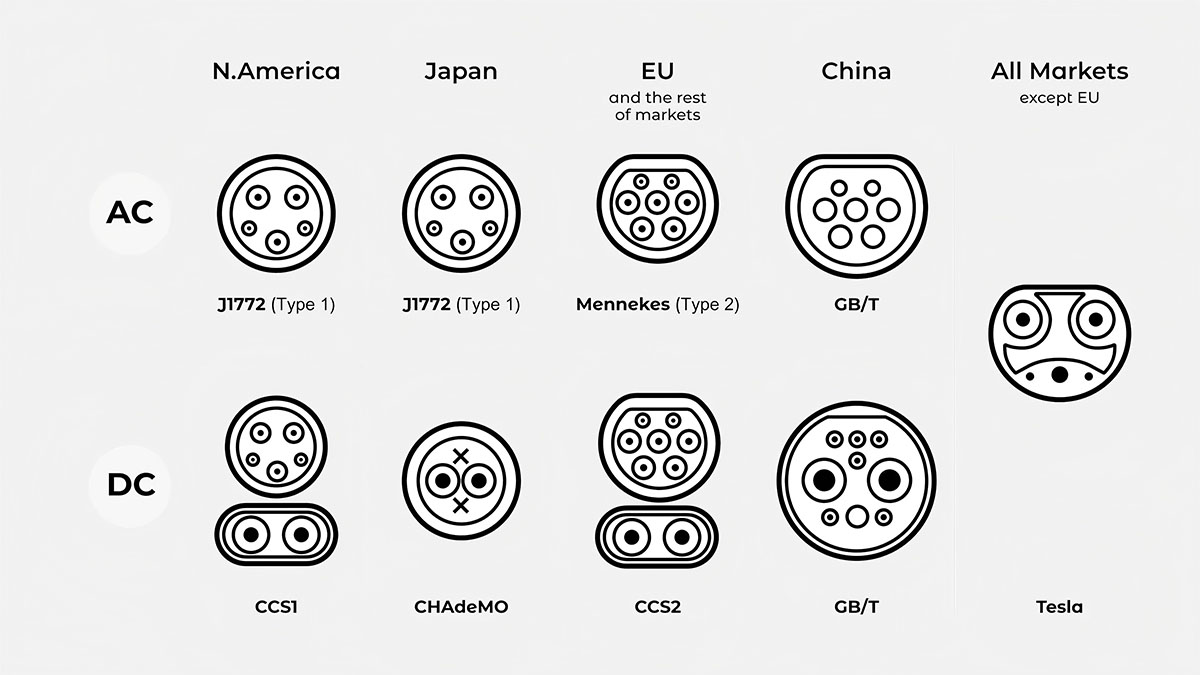

EV Charging Adapter Guide 2026: CCS1, CCS2, NACS, Type 1, Type 2, and GB/T

EV Charging Adapter Guide 2026: CCS1, CCS2, NACS, Type 1, Type 2, and GB/T

Jul 15, 2025

EV charging adapters solve one clear mismatch: the connector on the charger does not match the inlet on the vehicle. They are not for extra reach, and they are not a fix for “it plugs in but won’t charge.” If the connector already matches and charging still fails, the cause is usually authentication, station faults, vehicle settings, communication, or a protection trip.

What an EV charging adapter is

An EV charging adapter connects two different connector standards so they can mate safely within defined limits. In many AC cases, that can be a passive conversion adapter that preserves grounding/earthing continuity and correct control signaling. In DC cross-standard projects, the situation can be more demanding. Depending on the pairing and the environment, compatibility may require system-level validation and, in some cases, a dedicated conversion solution rather than a simple “shape adapter.”

An adapter is not an extension cable. It cannot add DC fast charging to an AC-only vehicle. It also cannot bypass site or vehicle restrictions. Even when two ends fit mechanically, a session may fail due to system expectations or allowed-use constraints, especially in DC fast charging environments.

AC adapters and DC adapters

AC charging and DC fast charging place very different demands on an adapter.

With AC charging, the vehicle’s on-board charger converts AC to DC inside the car. The adapter must handle continuous current safely and keep pilot/proximity signaling stable.

With DC fast charging, the station sends high-current DC directly to the vehicle. Heat, contact stability, and locking/release behavior become much more important. For DC cross-standard deployments, treat the adapter as part of the power path and plan validation accordingly.

Before you buy: three checks that decide compatibility

First, confirm whether you are charging on AC or DC. This determines the risk level and what matters in selection.

Second, write down both ends as a pair: vehicle inlet → charger connector. Shopping by a single connector name leads to avoidable mistakes.

Third, confirm whether the adapter is allowed and supported in your environment. For DC, the “allowed use” question can be as real as ratings. Check vehicle-side expectations and site-side rules early, before procurement.

Types of EV charging adapters

Type 1 ↔ Type 2 (AC)

This is common in mixed sites and cross-region travel when a Type 1 vehicle needs to use Type 2 AC infrastructure. In day-to-day use, continuous current handling, stable signaling, and mechanical strain relief decide reliability more than connector names.

Type 2 ↔ Type 1 (AC)

This shows up in imported-vehicle scenarios and mixed sites with Type 1 infrastructure. Consistent behavior across different EVSE brands matters. Outdoor handling adds another layer: sealing, materials, and a body design that stays stable when exposed to water, dust, and temperature swings.

NACS ↔ Type 1 (AC)

For AC use during a transition period, the practical success factors are still the basics: stable fit, steady current handling, and consistent control signaling. Most real failures in the field come from poor mechanical fit or underrated components rather than “mystery incompatibility.”

CCS1 ↔ CCS2 (DC)

This is used for cross-region fleets, validation programs, and deployments with mixed DC infrastructure. Choose by voltage class and sustained current for the real duty cycle you expect, not by a headline number. Locking/release behavior matters because many support issues start with disconnect or latch problems, not with charging speed.

NACS ↔ CCS (DC)

This has become a major category in North America. The key point is that DC access can be constrained by more than the physical interface. Vehicle-side requirements and site rules may determine whether charging is possible. If your goal is reliable DC access at scale, verify compatibility expectations and allowed use early, then move to thermal and mechanical selection.

CCS2 → GB/T (DC)

This pairing appears in project-driven deployments where CCS2-side systems need to interface with GB/T-centric environments. Treat it as a system-level topic, not just a connector topic. The practical requirement is end-to-end validation with the target vehicle and charging equipment, because DC cross-standard behavior may depend on more than mechanical fit. Plan engineering verification before rollout, especially for sustained operation and predictable connect/disconnect workflows.

CHAdeMO-related bridging (DC)

People ask about this because CHAdeMO still exists in some regions and older fleets. In practice, this category is constrained. It is often not a simple passive adapter purchase decision, and availability can be limited. If a project depends on a CHAdeMO bridging path, validate end-to-end behavior in the real charging environment before committing.

Adapter comparison table

Adapter type

Charging mode

Best fit

Key checks

Type 1 ↔ Type 2

AC

Travel, mixed AC sites

Continuous current handling, stable signaling, strain relief

Type 2 ↔ Type 1

AC

Imported vehicles, mixed sites

EVSE compatibility, sealing, stable fit

NACS ↔ Type 1

AC

Transitional North America AC

Fit quality, steady current handling, consistent signaling

CCS1 ↔ CCS2

DC

Cross-region DC operation

Voltage class, sustained current, heat performance, locking behavior

NACS ↔ CCS

DC

North America DC access

Allowed-use constraints, vehicle/site expectations, heat performance

CCS2 → GB/T

DC

Project deployments

End-to-end validation, sustained operation behavior, workflow fi

CHAdeMO bridging

DC

Legacy fleets only

System validation, availability constraints, environment fit

How to choose an adapter

Start with charging mode, then confirm rules and expectations, then confirm ratings. This order prevents most mistakes.

Selection flow:Identify AC or DC→ Confirm vehicle inlet standard→ Confirm charger connector standard at the site→ Confirm allowed use and compatibility expectations (especially DC)→ Match voltage class and sustained current needs→ Confirm thermal stability, locking/release behavior, and durability→ Deploy with clear labeling and simple user instructions

Two short scenarios

Scenario 1: A Type 1 vehicle at a site with Type 2 AC socketsThe adapter solves the physical mismatch, but reliability depends on sustained current handling and stable signaling. If the interface runs warm or becomes intermittent, common root causes are underrated components or mechanical strain from a heavy cable. The practical fix is choosing an adapter designed for daily continuous use and reducing side-load at the interface.

Scenario 2: A fleet moving between CCS1 and CCS2 DC sitesThe common failure pattern is selecting by connector names without checking sustained operation and heat behavior. A setup that works for short sessions can struggle in hot weather or longer sessions. Standardize a small set, validate under real duty cycles, and train drivers to end sessions properly before disconnecting.

Checks before deployment

Ratings that match real useContinuous and sustained use matters more than peak. AC charging can run for hours. DC puts sharp heat load into the interface.

Thermal behavior and contact stabilityHeat is often the first sign of trouble. Avoid stacking adapters, because each interface adds resistance, heat, and mechanical stress.

Locking and release behaviorA good adapter feels consistent and does not require unusual force. For DC, predictable locking and safe release behavior matter most.

Durability and environment fitOutdoor handling introduces water, dust, grit, and temperature swings. Choose hardware that survives poor conditions, not only ideal conditions.

Labeling and handlingAdapters move between vehicles and sites. Clear labeling reduces misuse. For fleets, a short instruction card prevents avoidable downtime.

Common mistakes

Using an adapter to solve reach. That is a cable or site design problem, not a conversion problem.

Stacking adapters. This increases resistance, heat, and mechanical stress.

Assuming “DC is DC.” Ecosystem expectations and allowed use can block sessions.

Shopping by connector names only. Sustained current and thermal margins decide real reliability.

Workersbee EV charging adapters

Workersbee offers a focused set of conversion adapters for common cross-standard needs: Type 1 to Type 2 and Type2 to Type1 for AC charging, and CCS1 to CCS2, CCS2 to CCS1 for DC project scenarios. These products are intended for connector mismatch cases where the vehicle inlet and the charger plug follow different standards and need a stable interface.

For cross-standard projects, we support customers in confirming the correct pairing and application boundaries early, so the selected adapter matches the charging mode (AC vs DC), the duty cycle, and the deployment environment. This helps reduce mismatch risk in mixed fleets and cross-region rollouts, and makes it easier to standardize a practical adapter set across sites.

FAQs

Can an adapter add DC fast charging to my car?No. If the vehicle does not support DC fast charging, an adapter cannot add that capability.

Can I stack adapters?Avoid it. Each interface adds resistance and heat, and stacking increases mechanical stress and failure points.

Why does a station reject an adapter even though it fits?Physical fit is only one layer. For DC environments, ecosystem expectations and allowed use can block sessions.

Do I need different adapters for home and public charging?Often, yes. Home is usually AC. Public can be AC or DC depending on the site. Start with charging mode.

Read More

EV Charging Adapter Guide 2026: CCS1, CCS2, NACS, Type 1, Type 2, and GB/T

EV Charging Adapter Guide 2026: CCS1, CCS2, NACS, Type 1, Type 2, and GB/T