Are All Level 2 EV Chargers the Same?

Are All Level 2 EV Chargers the Same?

Nov 05, 2025

They aren’t the same. Real-world speed is capped by the lowest of three limits: your home circuit capacity × the charger’s rated output × your vehicle’s onboard charger (OBC). On top of that, units differ in installation style, smart features, weather protection, and plug type.

Charging Power Isn’t Equal

Amps translate to kilowatts (kW) by multiplying volts × amps ÷ 1000. On a typical 240 V supply, 32 A is roughly 7.7 kW, 40 A about 9.6 kW, and 48 A about 11.5 kW. Some hardwired models support up to 80 A (≈19.2 kW), but that only helps if your panel, branch circuit, wiring, and vehicle can accept it.

Most homes land in the 40–60 A circuit range for a dedicated Level 2 circuit. Because EV charging is a continuous load, the rule of thumb is to use no more than 80% of the breaker rating for sustained charging. A 50 A breaker therefore supports about 40 A of continuous charging; a 60 A breaker supports about 48 A.

When does 19.2 kW make sense? If you have the service capacity, a short wiring run, a vehicle with a high-power OBC, and a need to turn cars around quickly. If your vehicle’s OBC tops out at 7.2–11 kW—as many do—going beyond 48 A won’t change your actual charge speed.

Amps → kW → circuit → typical use case

Charger rating (A)

Approx. kW @ 240 V

Typical breaker (A)

Common use case

32

~7.7

40

Daily home charging, most PHEVs/BEVs

40

~9.6

50

Faster home charging on mid-size panels

48

~11.5

60

Upper end for many homes, OBC-limited vehicles benefit

80 (hardwired)

~19.2

100 (dedicated)

High-capacity homes, commercial/private fleets, high-OBC cars

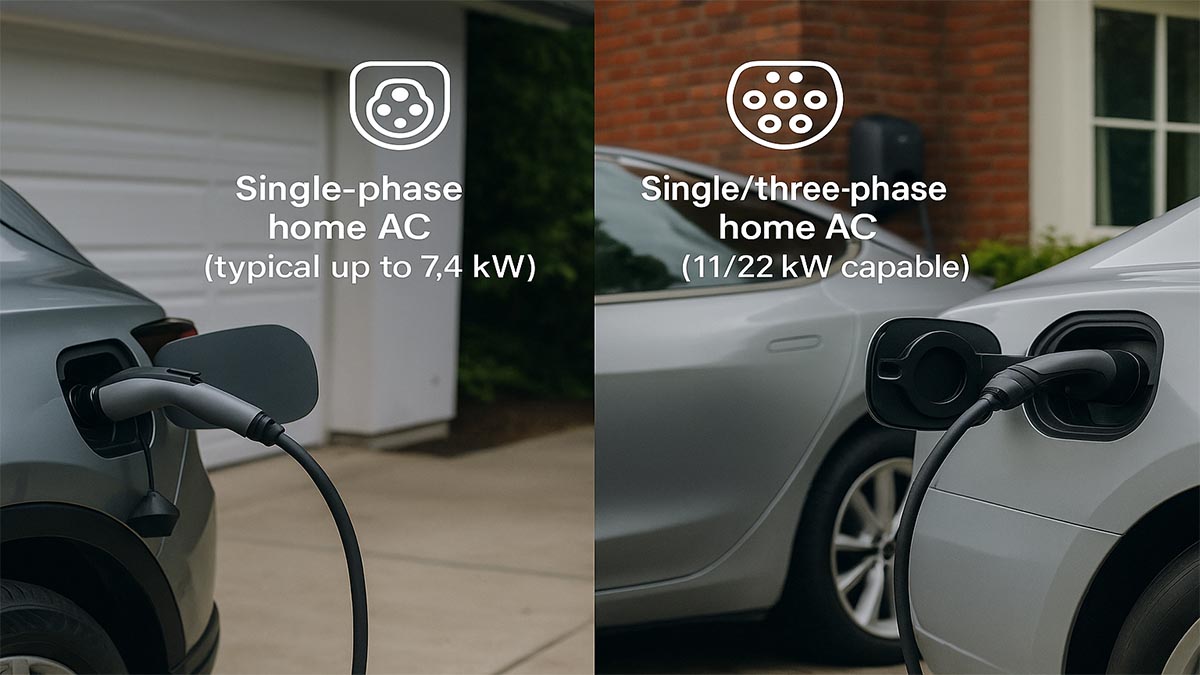

Plug Types & Compatibility

If your car uses J1772 for AC, any J1772 Level 2 unit will physically fit. If your car’s inlet is NACS/J3400, you’ll either use a native NACS unit or a compliant adapter depending on what came with the vehicle and local availability.

Tethered (fixed-cable) units are convenient and tidy; socketed designs accept interchangeable leads and can simplify replacement.

Cable length matters: too short and it’s awkward; too long and it’s heavier and more prone to scuffs. Good strain-relief and proper hanger placement extend cable life. For garages vs outdoor driveways, think about cable routing, drip loops, and where the handle rests out of rain and sun.

Smart vs Basic

“Smart” features automate the boring parts. Scheduling lets you charge off-peak and finish before you leave. Metering shows kWh and cost. Power-sharing (load balancing) allows two or more ports on one circuit without tripping breakers. Firmware updates fix bugs and add capabilities over time.

Some newer ecosystems advertise bidirectional readiness (vehicle-to-home or vehicle-to-grid). Whether you can use it depends on your car, your home electrical gear, and local rules.

A basic unit still makes sense if your rates are flat, you have a single car, and you prefer a set-and-forget setup. Smart becomes valuable when you juggle time-of-use pricing, share a circuit, or want data and remote control.

Install & Safety Basics

Hardwired installs are tidy and support higher currents; plug-in units (NEMA 14-50 or 6-50) are flexible and simpler to replace. Follow derating rules for continuous loads and respect the plug’s own current limits—don’t pair a 48 A charger with a 14-50 receptacle and expect 48 A continuous.

Before running conduit, check panel capacity, available breaker spaces, service size, and the path from panel to mounting location. Long runs and tight conduit bends add cost and reduce headroom.

For outdoors, look for enclosures with appropriate ratings (for example NEMA 3R, 4, or 4X; or IP66/67) and certification marks such as UL or ETL. GFCI protection is required; modern EVSE manages this internally, but your electrician will ensure the whole system meets code.

Cable management is part safety, part longevity: mounts and holsters keep the handle off the ground, avoid trip hazards, and reduce strain on the cable.

How Long Will It Take

Level 2 spans roughly 7–19 kW. A medium BEV battery can go from low state-of-charge to 80% in about four to ten hours depending on effective power. PHEVs, with smaller packs, are typically full in one to two hours.

Two quick examples:• OBC-limited: Your car accepts 7.2 kW max. Even with a 48 A unit on a 60 A circuit, you’ll still see ~7.2 kW.• Circuit-limited: Your car can take 11 kW, but you installed a 32 A unit on a 40 A circuit; you’ll get ~7.7 kW.

Micro-table

Battery size (kWh)

Effective kW

Approx. hours to ~80%

50

7.7

~5.2

60

7.7

~6.3

75

9.6

~6.3

82

11.5

~5.7

100

11.5

~7.0

(Estimates assume near-linear charging on AC; real times vary with temperature, starting SOC, and vehicle settings.)

Decision Graphic

Think in a straight line:Home circuit (breaker and wiring in amps) → EVSE rating (amps) → Vehicle OBC (kW). Convert amps to kW at 240 V where needed. The smallest of these three becomes your effective charging power. From there, divide usable battery kWh by effective kW to estimate hours.

Small side notes: the 80% continuous-load rule applies; very long cable runs and high ambient temperatures can nudge results down a bit.

FAQ

Are higher-amp chargers always faster?Not automatically. Charging speed is capped by the lowest of three limits: your circuit, the charger’s rating, and your car’s onboard charger (OBC). If your OBC is 7.2 kW, a 48 A unit on a 60 A circuit won’t exceed ~7.2 kW. Higher amperage helps only when all three can support it. Think of amps as headroom—you benefit only if the rest of the system can use it.

Do I need hardwiring for 48 A or above?In practice, yes. Plug-in setups (e.g., NEMA 14-50/6-50) are typically used at 40 A continuous due to the 80% rule for continuous loads and receptacle limits. To run 48 A continuously, most jurisdictions and manufacturers call for a hardwired install on a 60 A circuit with appropriately sized conductors. Hardwiring also reduces heat at the connection and avoids receptacle wear over time.

Can I mount outdoors year-round?You can, if the unit and install are rated for it. Look for enclosures marked NEMA 3R/4/4X or IP66/67, a UV-resistant cable, and a holster that keeps the handle off the ground. Add a drip loop, keep terminations inside a weather-rated box, and avoid direct sprinkler spray or standing water. In snowy or salty climates, stainless hardware and a 4X enclosure resist corrosion better.

Is 19.2 kW (80 A) worth it at home?Only if three boxes are ticked: your service and wiring can support a dedicated high-amp circuit, your vehicle accepts >11 kW AC, and you gain real value from shorter dwell times. Many cars cap AC at 7–11 kW, so you’d see no speedup. High-amp installs also cost more (panel upgrades, thicker cable, longer conduit runs). If you rotate multiple EVs nightly or have a large battery and tight schedules, it can make sense.

Will NACS replace J1772 support for my current car?Not in a way that strands you. AC charging remains interoperable via adapters and mixed-standard infrastructure during the transition. If you own a J1772-inlet vehicle, a J1772 wallbox remains a safe choice; if you move to a NACS-inlet vehicle later, you can use an adapter or replace the cable on some units. Prioritize certification and enclosure rating over chasing the newest plug logo.

What’s Changing in 2025–2026

Higher-current AC units are appearing alongside better power-sharing for multi-car homes and small fleets. Some ecosystems are piloting bidirectional functions, but broad, turnkey use still depends on matched vehicles and home hardware. Plug landscapes are converging, yet day-to-day home AC charging remains familiar: pick the right current, install cleanly, and let the OBC set the ceiling.

Choose a charger by matching three things: the circuit you can safely support, the charger’s rated output, and your vehicle’s OBC. After that, decide how much “smart” you want, and make sure the enclosure and cable setup fit where you’ll actually park. This approach avoids over-buying, under-installing, and disappointment with real-world speed.

Read More

Can You Use Your Electric Car While Charging?

Can You Use Your Electric Car While Charging?

Are All Level 2 EV Chargers the Same?

Are All Level 2 EV Chargers the Same?

What Is EVSE? A Complete Guide to Electric Vehicle Supply Equipment and How It Works

What Is EVSE? A Complete Guide to Electric Vehicle Supply Equipment and How It Works

What Is EV Range? A Simple Guide for Everyday Drivers

What Is EV Range? A Simple Guide for Everyday Drivers

The Practical Guide to Type 2 EV Charging Cables

The Practical Guide to Type 2 EV Charging Cables

SAE J1772 Type1 VS IEC 62196 Type2? How to Choose

SAE J1772 Type1 VS IEC 62196 Type2? How to Choose

Smart EV Charging Explained: A Simple Guide

Smart EV Charging Explained: A Simple Guide

7 Cable Habits That Kill Your EV Charger — and What To Do Instead

7 Cable Habits That Kill Your EV Charger — and What To Do Instead

What Is the Tesla NACS Connector (SAE J3400)?

What Is the Tesla NACS Connector (SAE J3400)?

What is the J1772 Connector and Why it Matters in 2025

What is the J1772 Connector and Why it Matters in 2025

Type 1 vs Type 2 EV Charger Differences: What to Choose and Why (US & EU)

Type 1 vs Type 2 EV Charger Differences: What to Choose and Why (US & EU)

What Is a Type 2 EV Connector? A Plain Guide to the 7-Pin AC Plug (2025)

What Is a Type 2 EV Connector? A Plain Guide to the 7-Pin AC Plug (2025)